White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Netbiter is helping Yemen manage deliveries of diesel fuels across the country, supplying generators at hospitals, potable water pumping stations, and many other important installations.

Yemeni systems integrator InPro for Importing has worked with the government’s Ministry for Telecommunications to develop and maintain a reliable nationwide network of 400 base station transceivers (BSTs) to enable real-time monitoring of local fuel supply levels. This allows fuel arriving at the country’s seaports to be distributed to those regions in greatest need of replenishment.

Yemen is located at the southern end of the Arabian Peninsular. It has borders with Saudi Arabia and Oman, plus about 2,000 kilometers of coast line and 200 islands. The total land area is around 500,000 square kilometers and the population, currently 27,000,000, is growing rapidly.

The country suffers from near-continuous armed conflicts, which has severely disrupted supplies of water, food and fuel. In an effort to help fix the country’s infrastructure, the United Nations is providing $2 billion in aid. However managers need to know which regions have supplies in hand and which need deliveries, which means keeping information up to date and accurate so that supplies are not misdirected - intentionally or unintentionally.

The Ministry of Telecommunications asked Inpro, which has a background in systems integration and remote communications, to develop an internet-based network of local communications hubs or BSTs that can monitor the available fuel supplies. A survey revealed that several suitable BSTs are already installed around the country so it was decided to utilise these, supplementing them with additional ones where necessary.

InPro quickly realised that the existing BSTs used a variety of equipment from different manufacturers and also different communications protocols. Thus integrating them would present some challenges; fortunately it had experience of similar requirements on previous projects and knew of several possible solutions. It would have been prohibitively expensive to specify a standard suite of equipment and protocols and convert all the existing base stations to this. Instead it was decided to use protocol converter technology to enable all the base stations to communicate freely across the network.

In detail, the architecture of the network is based on a new Industrial Internet of Things (IIoT) system that covers the whole of the country and provides 24 hours per day communication. InPro decided to use an Ewon Netbiter as the main gateway, a product it had used successfully on other projects.

In the future, whole industries will maximize productivity with IIoT and industry 4.0

Osama A. Nasher, General Manager, InPro for Importing

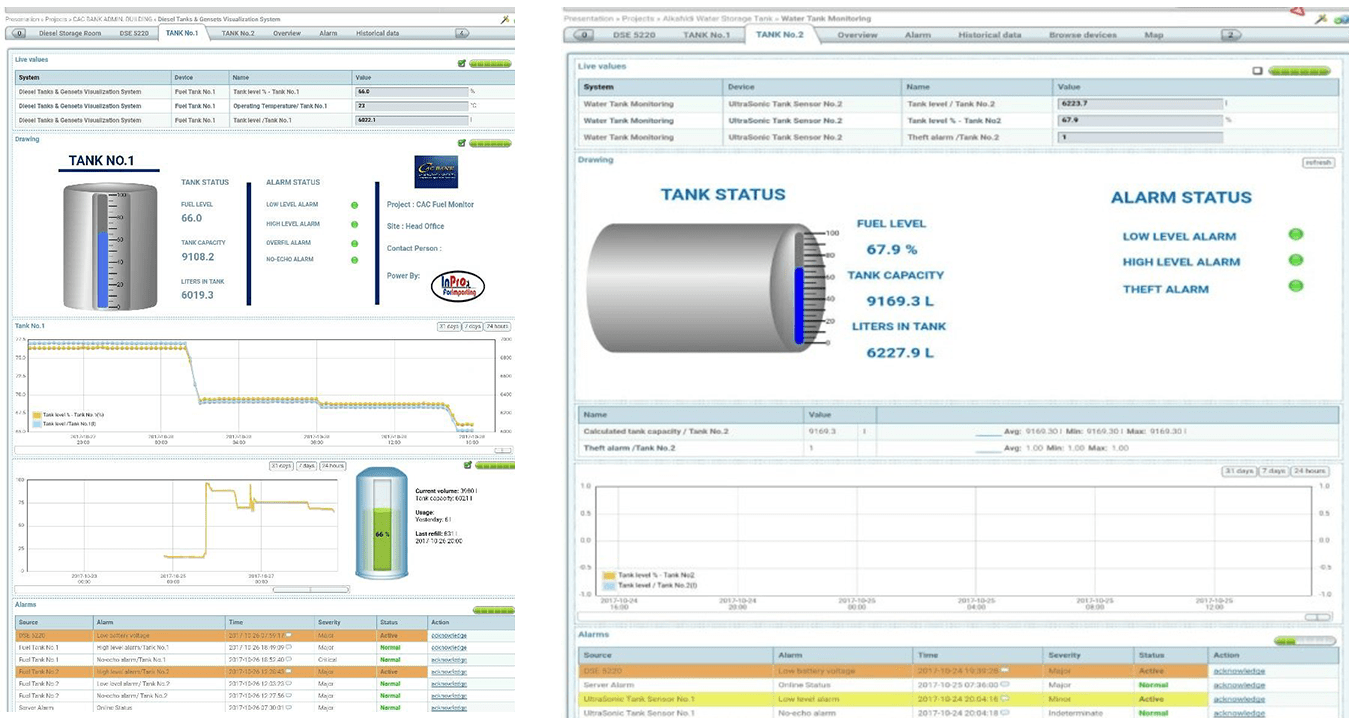

Ewon Netbiter is a complete hardware and software solution that enables remote management of installations online. It consists of Netbiter edge connectivity gateways which allow field equipment to directly connect to Argos, a secure cloud-based IIoT management platform that provides users with customized dashboards, reports, trend analysis and alarm management. With it users can communicate with all the nodes in the network to visualise, analyse and manage plant and equipment all over the country. It has previously been used in power generation, industrial automation, building control, HVAC, water and wastewater, telecoms, security and petrochemical applications.

Since the Netbiter solution comes with a ready-made GUI, In Pro for Importing can easily set up graphical dashboards which show current values in an intuitive way.

Ewon Netbiter can support almost any industrial equipment, using Modbus RTU/TCP, J1939 or EtherNet/IP protocols and it has multiple ports for serial/Ethernet or I/O connectivity. It is fully scaleable, so networks can be extended or reconfigured as required.

On the Yemeni fuel project, Netbiter’s basic role is to network level sensors that monitor the amount of diesel stored in tanks all over the country, to an accuracy of 0.25%. This data is then mapped out and compared with recent trends and usage reports so that managers can see which areas are most in need of resupply.

The fuel pumps have also been integrated into the network, so that calculations are based on up-to-the-minute data. For maximum effectiveness, the managers retain the discretion to include other external information, such as a request for emergency supplies from a busy hospital, in their decision making processes.

The system is now up and running and Inpro says it is proving to be an invaluable asset in the vitally important function of fuel distribution. In fact it is already in discussions with the Ministry about extending the network and other developments.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.