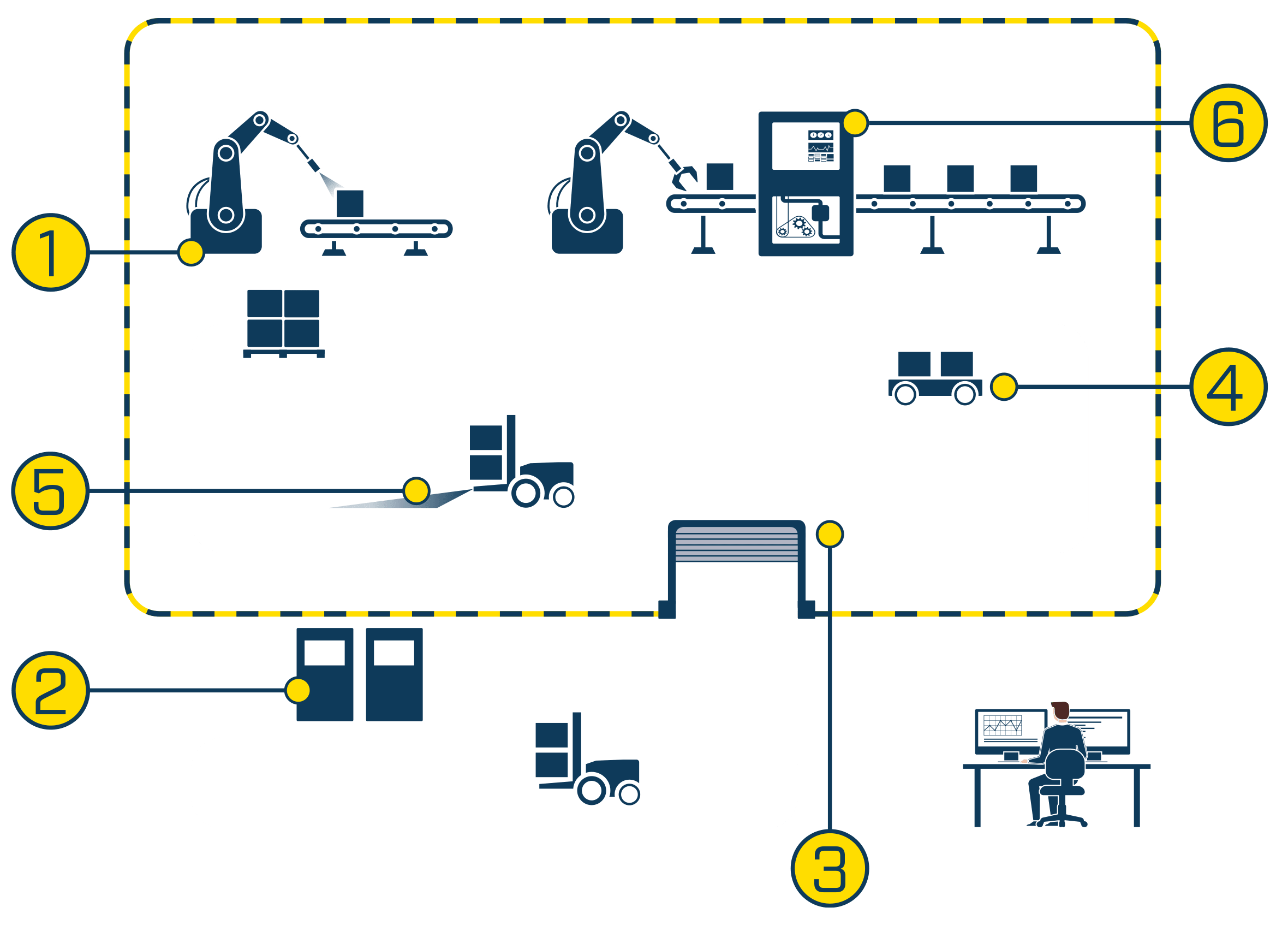

Ensuring safety where people and machines interact

- People and machines collaborate closely

- Equipment moves or operates autonomously

- Loads or vehicles pose a risk to workers

Need to keep people safe around machines? Struggling to meet complex safety standards? Looking for a faster, easier way to develop and certify your safety systems? HMS makes it simple. Our flexible, TÜV-certified solutions help you meet functional safety requirements with less effort, less risk, and more confidence.

With 15+ years of experience, HMS helps you deliver certified, trusted safety solutions:

Whether you're adding safety to a compact device or building a complex automation system, we’ve got you covered.

Every application is different. That’s why we offer four flexible, future-proof solutions to match your in-house capabilities and time-to-market goals:

Not sure which option is best for your application?

Functional safety is crucial in engineering because it ensures that systems, machinery, and devices operate reliably, even in the presence of faults or errors. It involves implementing safety measures, like redundancy and error detection, to prevent accidents or failures, particularly in critical applications like automotive control systems and industrial processes, where human safety and asset protection are paramount. Failure to achieve functional safety can lead to catastrophic consequences.

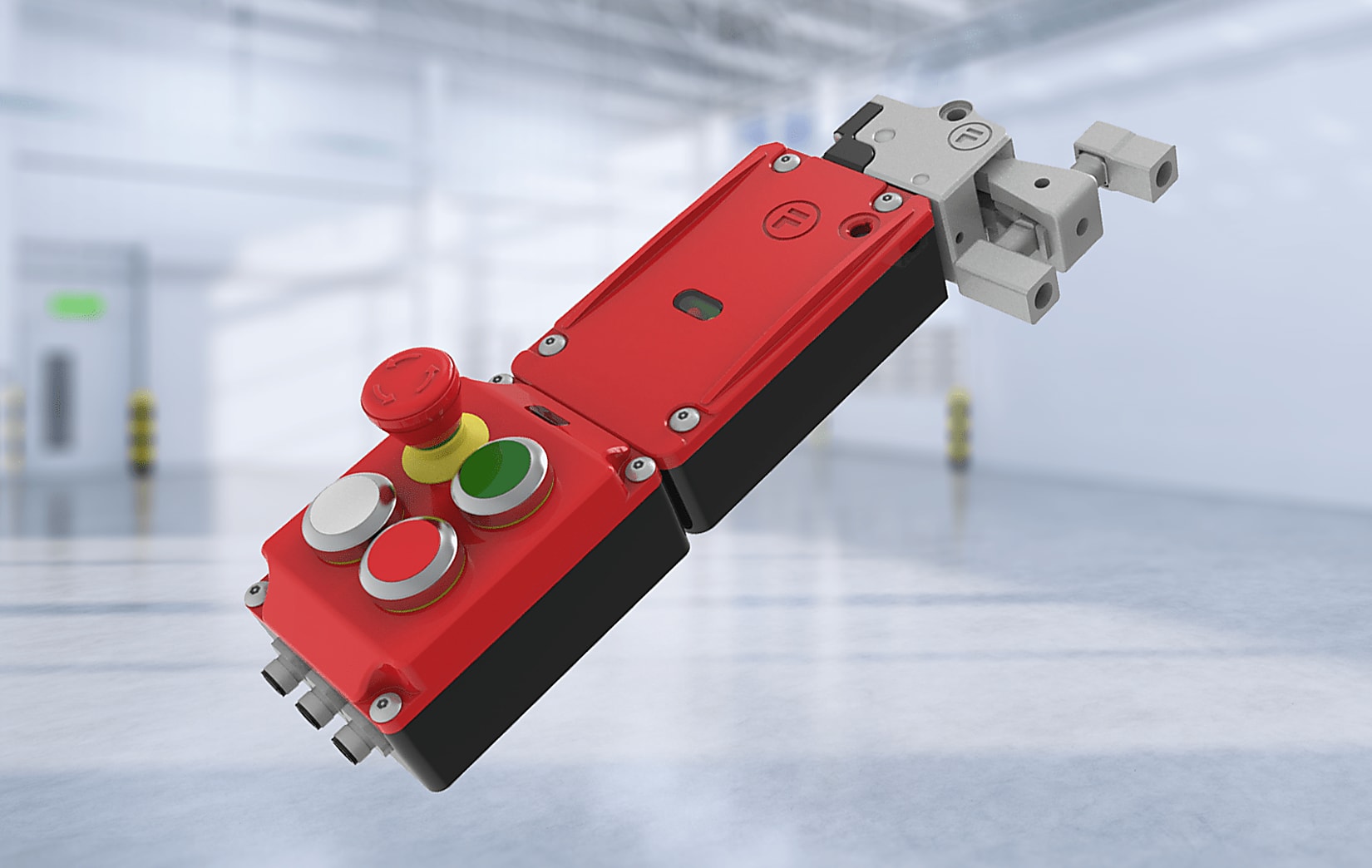

Yes. HMS offers the Anybus Safe2Link Remote IO device, a rugged, plug-and-play solution for adding functional safety to machines with minimal integration effort. It enables safe communication of local safety I/Os via CIP Safety over EtherNet/IP and includes advanced safety functions like SafeBound™ and SS1-t. It's ideal for mobile systems and industrial applications where fast deployment and certified safety are essential.

Using the T100 Safe IO module, the safe digital output signal can be directly connected to either a safe power-breaker relay or the STO input of the drive controller. With the access to the fieldbus provided by e.g. the Anybus CompactCom module, the STO function can be remotely controlled via the safety fieldbus protocol.

No, the safe outputs of the T100 are solely controlled via the safety fieldbus network. However, the Safe2Link product series (Safe2Link Pure IO and Safe2Link Remote IO) provide the SafeBound™ function. This implements a configurable safe I/O logic that allows local safe inputs to directly control local safe outputs, helping reduce the safe reaction time in the application.

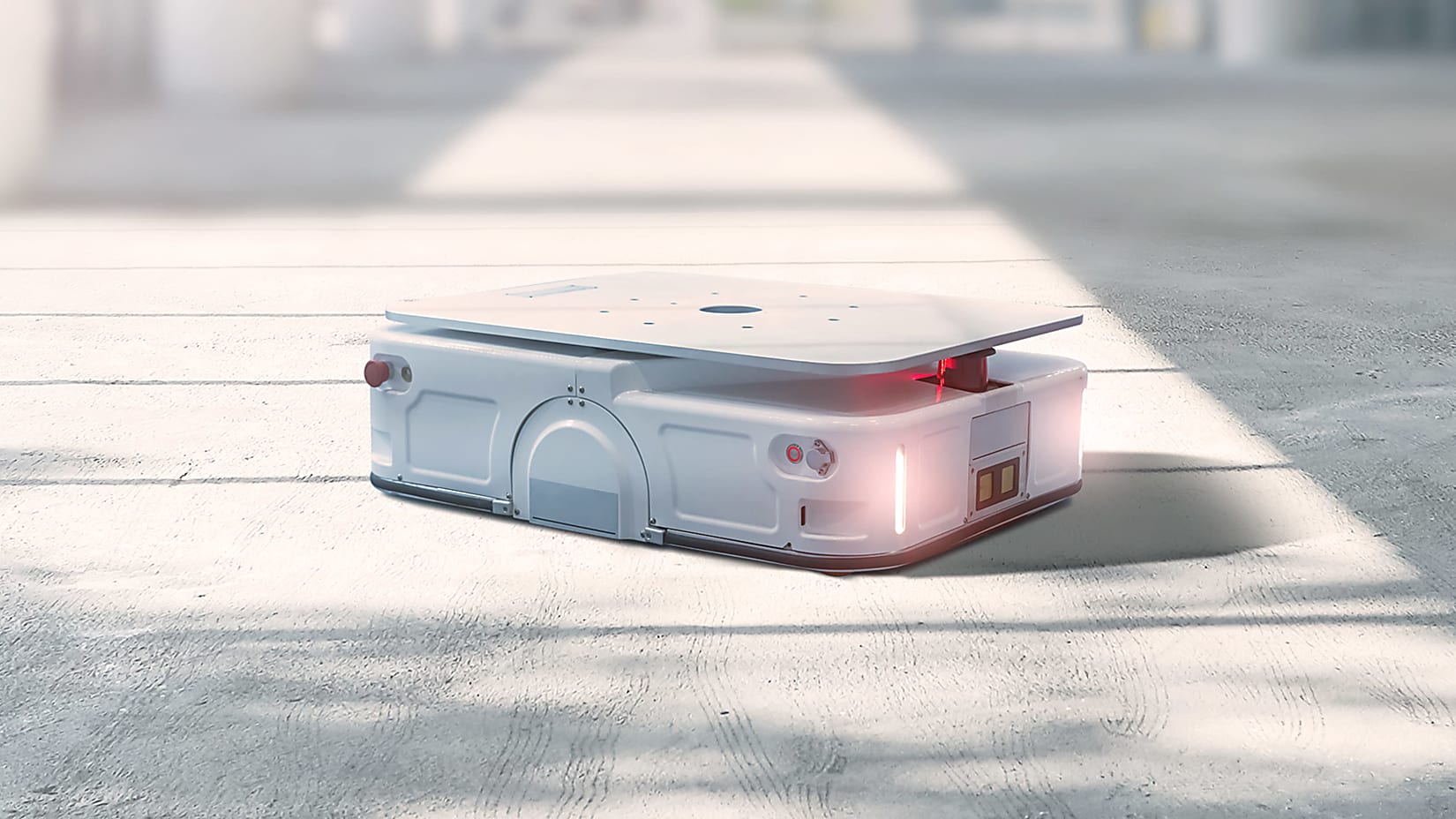

Functional safety is applied in various engineering domains, including automotive (ABS, airbags), aerospace (flight control systems), medical devices, and process industries. It is vital in industrial automation, robots, and AGVs (Automated Guided Vehicles), ensuring safe operation of machinery and autonomous systems, preventing accidents and harm to personnel in manufacturing, logistics, and material handling processes.

Functional safety is gaining significance in industrial automation due to emerging trends such as the proliferation of collaborative robots (cobots), the deployment of highly autonomous systems, and the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies. These trends emphasize the need to ensure safe operations in complex, interconnected industrial environments.

Join our on-demand webinar and take a deep dive into functional safety - a must-watch for anyone working in industrial automation or safety-critical systems.

TechTalk and technology introduction. Check our YouTube channel to see the latest videos.

Learn more about the new EU machine regulation and its effect on it using various practical examples.

Have a communication expert from HMS contact you to discuss your specific requirements.