White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

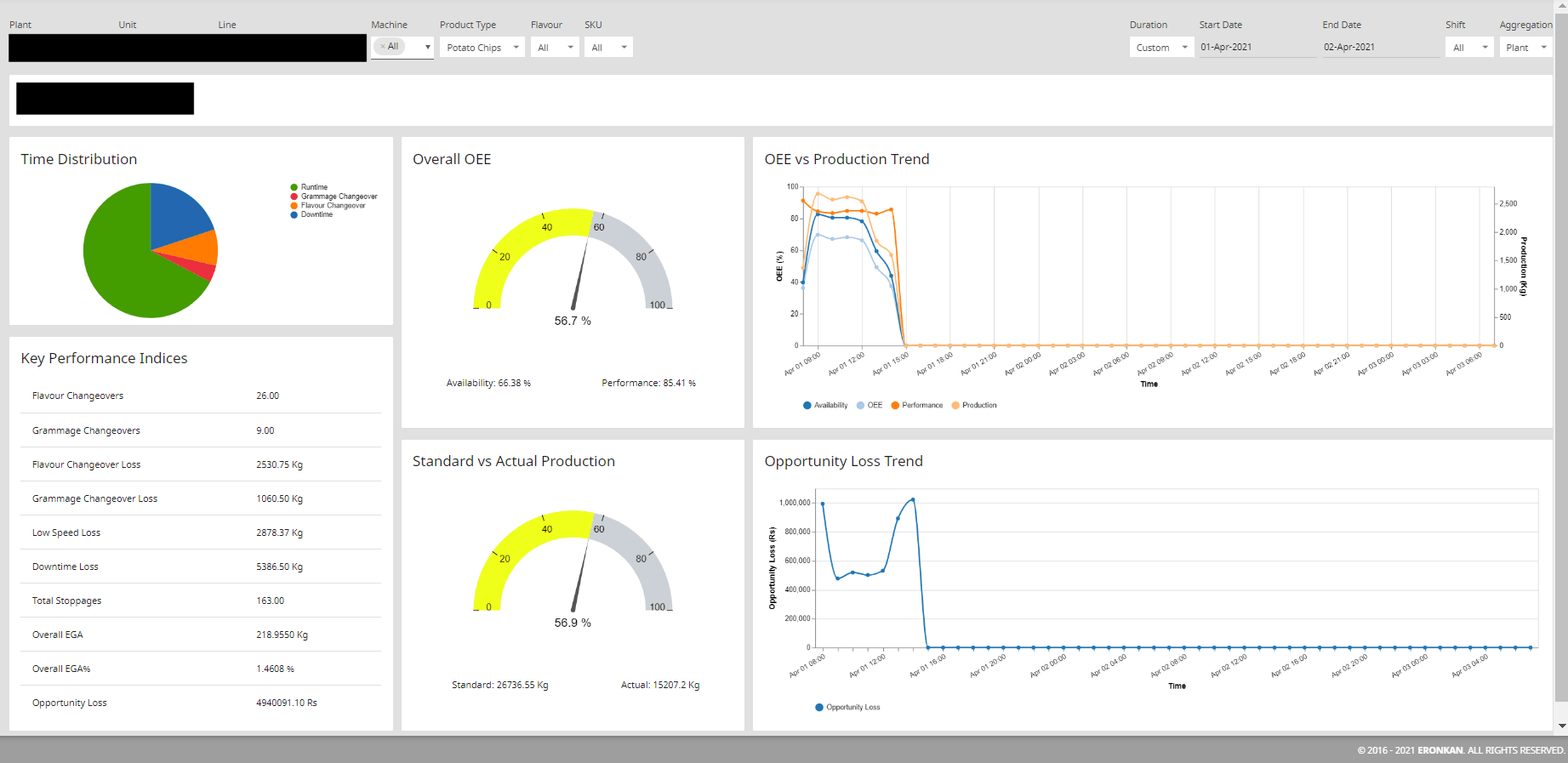

EroNkan's Industrial Platform offers IoT solutions for industries like food & beverage, packaging, and pharmaceuticals. They use Ewon Flexy gateways for secure data collection and analysis, leading to reduced losses, improved machine efficiency, and overall equipment effectiveness (OEE).

EroNkan’s Industrial Platform provides world-class infrastructure that enables IoT technology to be applied across various industries and verticals (food & beverage, packaging, pharmaceuticals, etc). It was created in 2014 by three co-founders who had worked together for a long time in previous companies, across different operating functions (shop floor hardware, control systems and enterprise software systems).

The drive behind EroNkan’s company has always been to create an Industrial IoT product of global standards within India itself. It started with the idea of extracting data from a transformer’s PLC, to now becoming a complete use case driven solution, successfully implemented in multiple companies.

EroNkan’s platform is focused on reducing losses (material, people, process, etc.) on the shop floor. Their goal is to improve machine efficiency and Overall Equipment Effectiveness (OEE). While exploring IIoT gateways for accurate data collection, the ability to integrate Industry 4.0 and new technologies into existing machines and heterogeneous systems was particularly crucial. This is indeed what allows EroNkan’s platform to provide the analytics & visualizations needed to understand what is happening on the shop floor. The Ewon Flexy respects this critical aspect, which made it the ideal choice.

Working with Ewon was a no-brainer. It has allowed us to standardize our field communication, reducing costs & efforts required in each implementation.

Kahaan Vasa, Business Development Manager, EroNkan

While searching for gateways, EroNkan discovered that the Ewon Flexy devices made it possible to communicate with most PLCs on the market (as well as legacy machines), thanks to a wide range of protocols.

Ewon’s expertise also came into play: "Ewon offers the most well-known and standard IoT gateway solutions out there and we wanted to work with a stable and trusted product for our data collection activities" says Kahaan Vasa, Business Development Manager at EroNkan.

The Ewon Flexy gateway reads the valuable information of the equipment (PLC variables) and creates a local buffer in order to prevent data loss (in case of internet interruptions). All data is smoothly and securely populated to the EroNkan cloud platform for storage; the application layer then comes into play with dashboards, reports and analysis.

EnroNkan use the Ewon Flexy devices to pull data from the shop floor, turning it into dashboards & reports on their cloud platform.

Thanks to the Ewon Flexy units, EroNkan has been able to collect very critical real-time data for their platform. They then run analytics to provide high value insights to their customers on things such as downtime, downtime reasons as well as Overall Equipment Effectiveness (OEE) analysis. It also helped optimize cables on the shop floor, by enabling data on a single protocol. Remote monitoring, downtime reduction and OEE improvements are some of the key benefits customers have gained from using EroNkan software platform. Kahaan Vasa explains: "In food companies, we have increased OEE by 3-5% and reduced machine downtime by up to 10% using the data we are armed with. One of the biggest improvements we made was also to reduce the finished goods loss by up to 3% for a company".

Leveraging existing data can therefore create tremendous value for better performance on the shop floor, while further enabling the workforce.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.