White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

HMS Networks’ Ixxat CAN topology solutions for control networks help to give used electric vehicle batteries a second life in stationary energy storage systems.

Connected Energy builds and operates second life battery energy storage systems. These extend the life of electric vehicle (EV) batteries in industrial and commercial-scale, stationary energy storage systems. EV batteries provide around 10 years of use on board vehicles before their charge holding capacity (and therefore electric vehicle range) reduces. If the batteries are recycled at this point a percentage of their value is lost and the financial and environmental cost of their disposal is high. Giving batteries a second life realises more of their value and reduces disposal issues.

By 2030 a million tonnes of EV batteries will be available for reuse and by 2035, global requirements for stationary energy storage could be completely met by second life batteries. Connected Energy has developed the E-STOR battery energy storage system to enable thousands of these batteries to be aggregated, controlled, and reused. Its technology has been proven, commercialised, scaled-up, and installed in the UK, Belgium, Germany, and the Netherlands. The biggest system currently in operation is 1.2 MW, but this will be surpassed in 2022 when several multi-megawatt schemes are expected to come on-line.

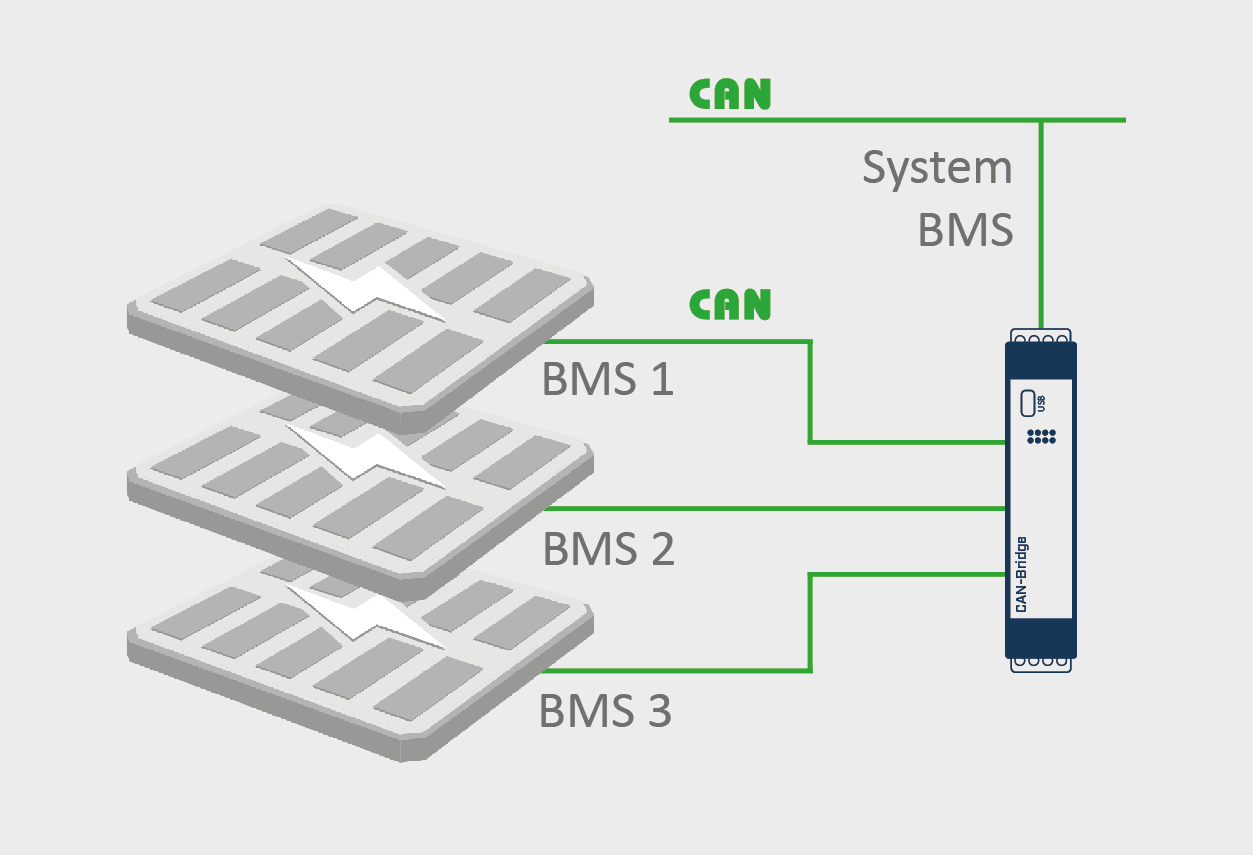

Jonny Cogman of Connected Energy explains the role of the Ixxat CANbridge NT 420: “We retain the OEM battery management systems (BMSs) for each of the individual second life batteries that we fit into our E-STOR systems. This means we can communicate with each battery, as and when required, and collectively the BMSs create the foundation layer of the system’s overall control system. For this purpose, it is of central importance for us that as many CAN channels as possible are available for communication. Reusing the existing BMS, giving them a second life also, maximises the ‘green’ credentials of the E-STOR brand.”

The BMSs use CAN (Controller Area Network) bus for sending and receiving control signals, reflecting their origins in the automotive sector. CAN was originally developed for on-board vehicle applications and allows the many microprocessors fitted to modern cars and other vehicles to communicate with each other’s applications without a host computer. However, it has also become a popular choice for other non-automotive applications, including general automation, motorised prosthetic limbs, electronic gear changes on sports bicycles and emerging fields such as EV charging stations.

By giving a second life to used electric vehicle batteries we are making maximum use of their embedded value, rather than wasting it through scrappage. Connected Energy E-STOR systems are a high-tech example of the circular economy in motion.

Jonny Cogman, Connected Energy Ltd

CAN uses a serial, message-based protocol and allows to minimise the amount of heavy and expensive copper wire used in vehicles. This means signals to and from each BMS are all sent along the same wires, or ‘bus’, with each signal having a header to identify it and keep it distinct from other signals. Importantly, high priority signals take precedence over less critical ones on the bus, so that there is always an immediate response for functions such as braking and turn signalling.

“There are many CAN solutions available on the market and we reviewed several before choosing to standardise on the Ixxat CANbridge solution from HMS Networks,” says Cogman. “The deciding factor was that it proved very easy to programme, but other benefits include that the CAN bridge is easy to install, while its robust build means that its long-term reliability is ensured. The longevity is particularly important because the life expectancy of an E-STOR installation is measured in years and decades.”

Using a CAN bridge for networking of the different BMS units and interconnection with the EMS.

The E-STOR control system architecture uses a CAN bridge for interfacing with the batteries, then steps up through layers of intermediate control using Modbus to the central (EMS) or overall controller. This manages the installation’s functional operations so that it can be switched in and out in response to demand; supplying power when needed and recharging when there is surplus power in the grid. Furthermore, the transmission of data such as temperature, voltage and current is done in this way.

Cogman sums up: “Our early installations were quite modest, typically 60 kilowatts, but everything was designed so that over time we have been able to scale up to megawatt systems and are now working on utility scale projects. The flexibility and adaptability of the Ixxat CANbridge NT 420 has let us design a control system architecture that is suitable for our range of installations.”

Company: Connected Energy Ltd

Country: United Kingdom

Solution: Ixxat network topology

Industries: Industrial automation / testing

Products: Ixxat CANbridge NT 420

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.