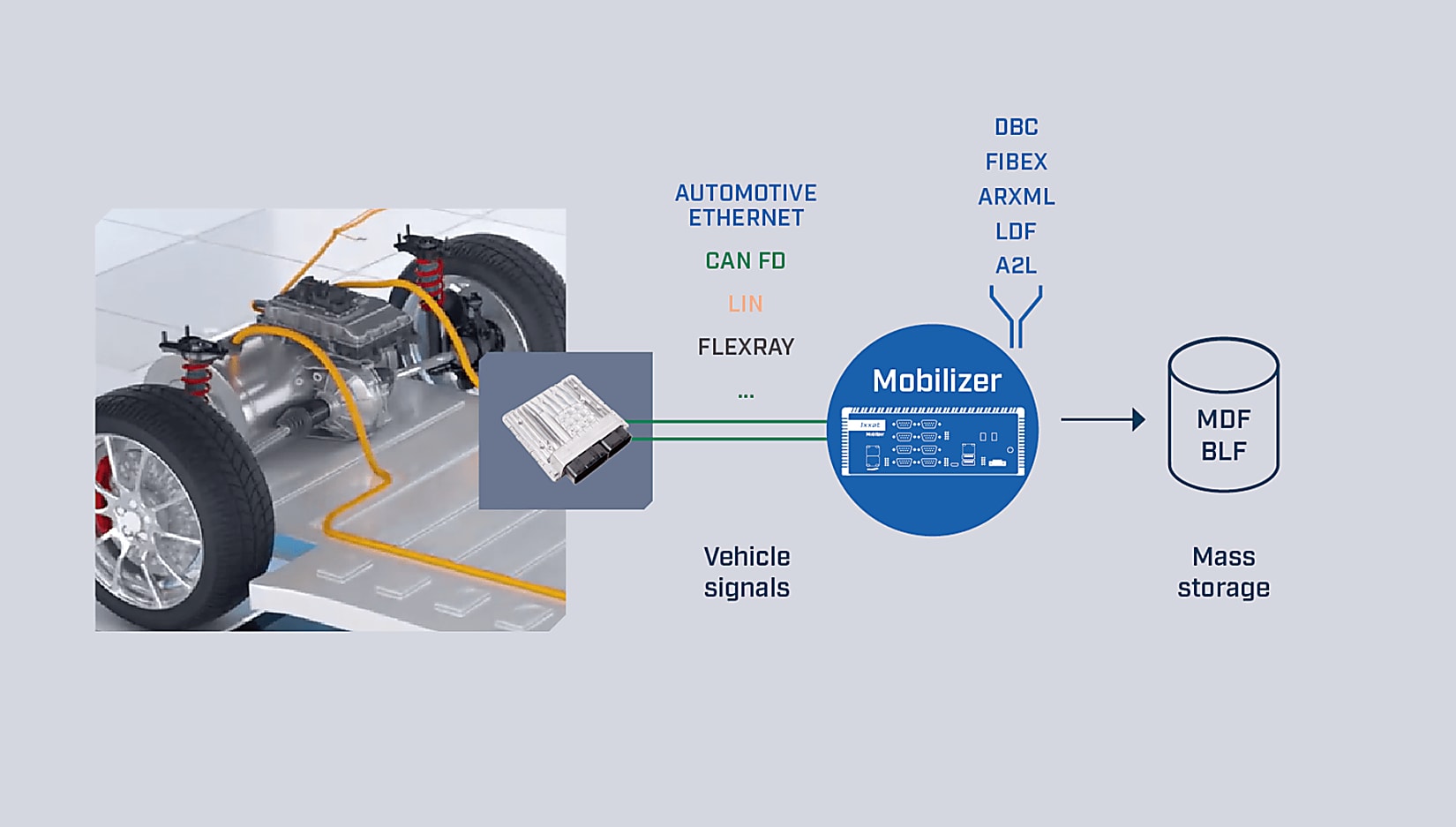

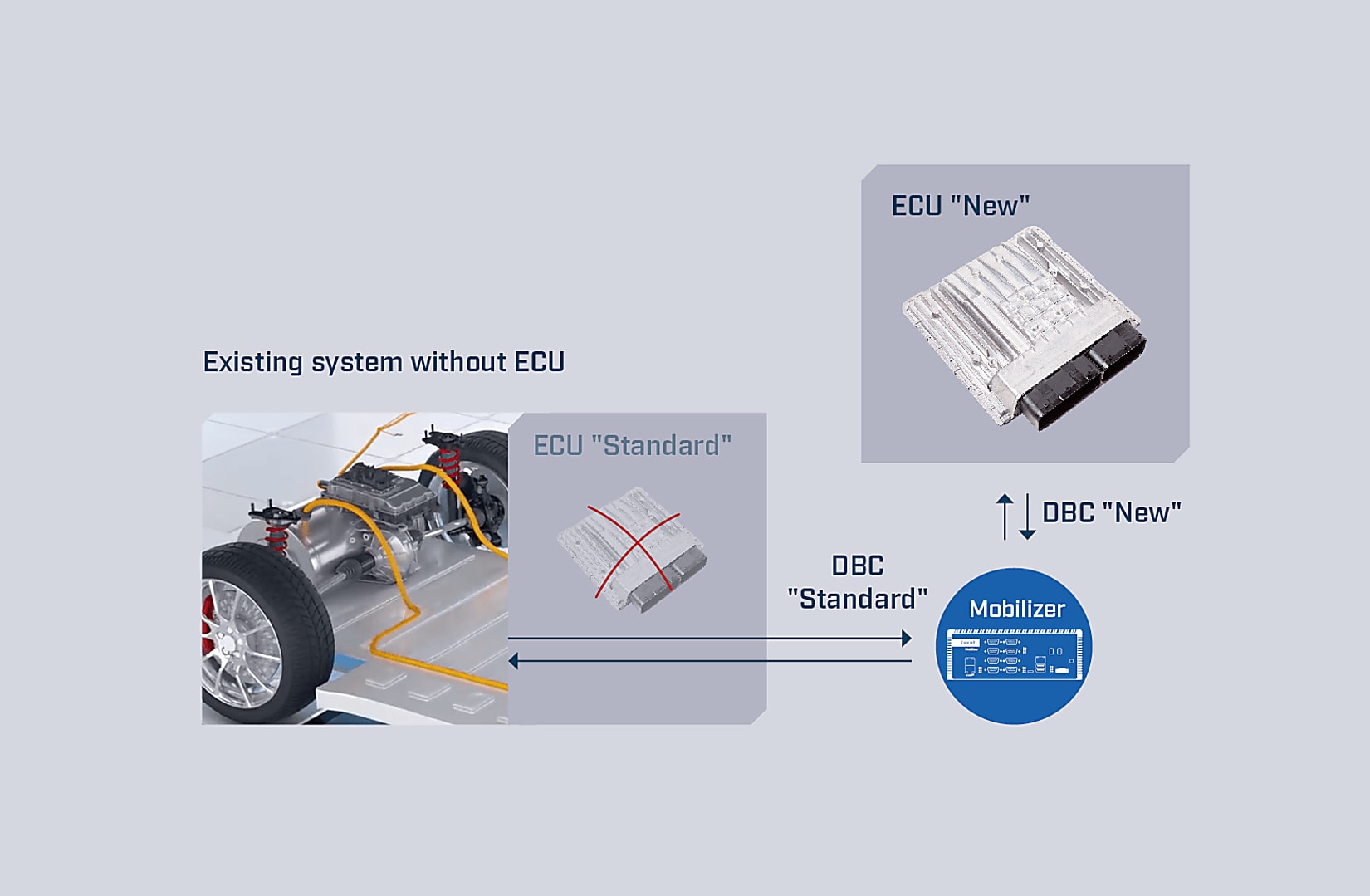

End-of-Line-Tests

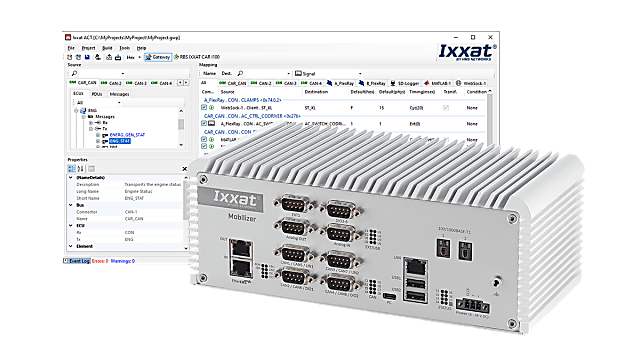

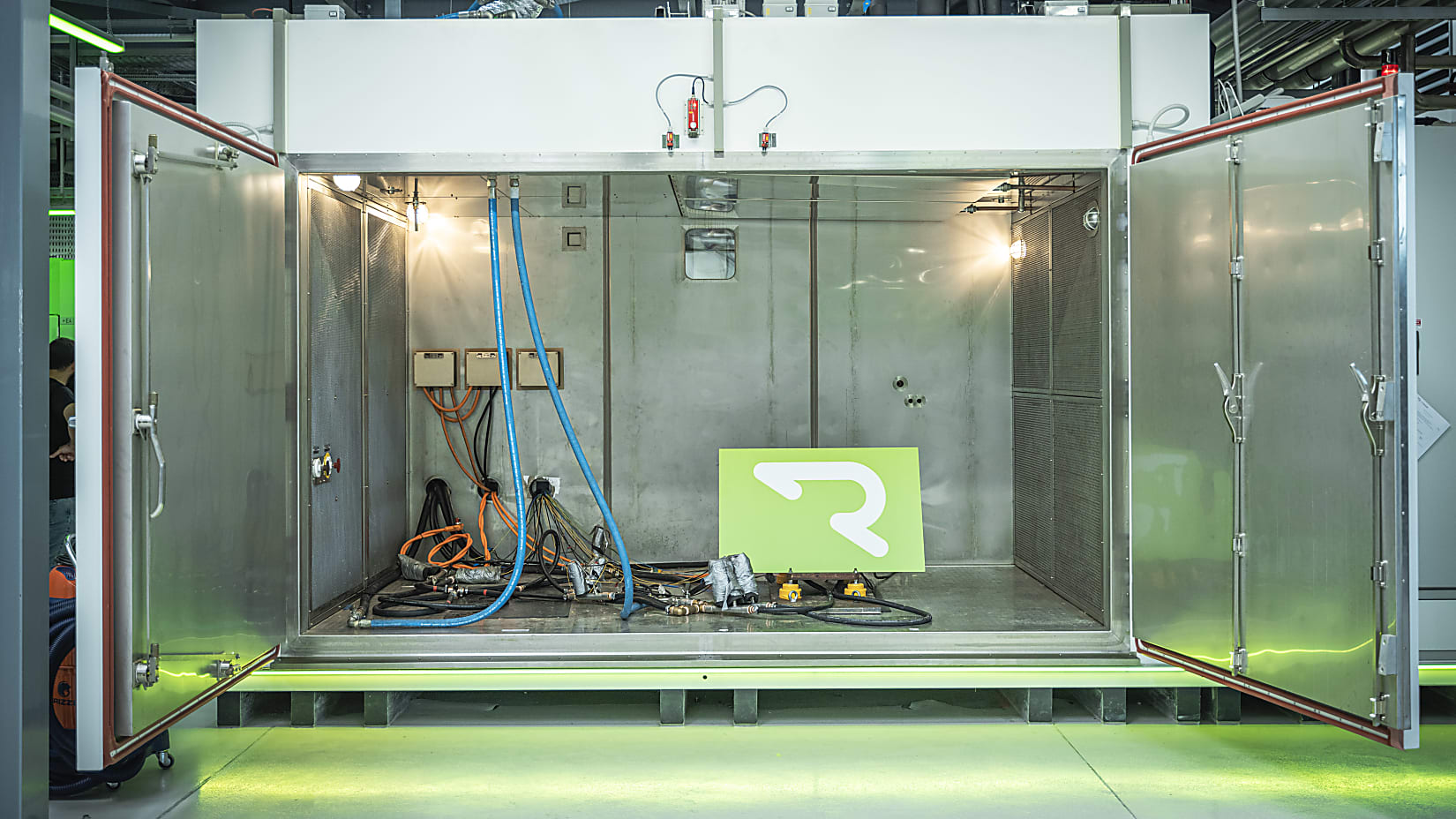

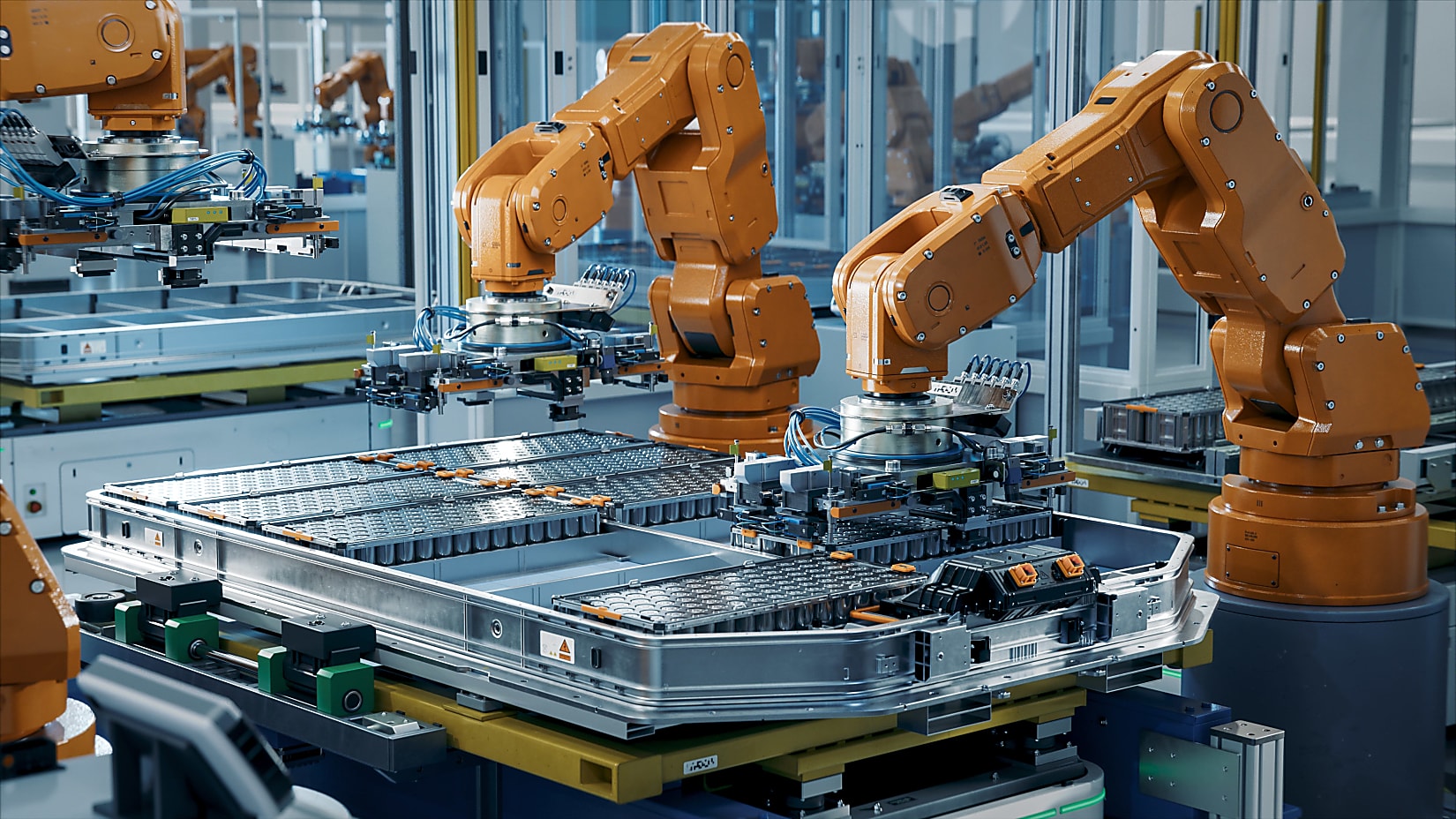

In end-of-line tests for battery-powered vehicles, different systems are communicating with each other under difficult conditions. In addition to cross-technology and cross-protocol communication when connecting the vehicle network to the automation system, it is also important to keep an eye on protecting the components from high overvoltages and EM influences. With products from HMS you can focus on the testing and leave the communciation tasks to us:

- BMS communication and flashing

- Connection to the automation system

- Rest bus simulation

- Overvoltage protection