White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Sarissa Assistance Systems rely on Ixxat INpact to connect their local positioning system to customer‘s own worker guidance systems.

Sarissa, based in southern Germany, supplies state-of-the-art assistance systems for position measurement and worker guidance with millimeter precision. Its ultrasonic systems enable error-free production and are used for fabrication and final assembly in battery production lines for the automotive industry, in the aerospace industry, and in other manufacturing facilities. Ixxat’s INpact multiprotocol fieldbus card enables PROFINET-based communication between the Sarissa system and the customer control unit.

Sarissa’s core expertise includes technology that locates a worker’s hands and handheld tools in three-dimensional space, and programming the algorithms needed for correct and reliable calculation of the coordinates. At the heart of the Sarissa system is the PositionBox, an innovative xyz coordinate sensor that makes it easy to determine the position of the hands and handheld tools in 3D without additional length and angle measurement systems.

When used with Sarissa’s QualityAssist software, the system assists workers in their tasks and decision-making with its innovative worker guidance functionality. Using laser projection instead of screen display enables particularly easy and intuitive worker guidance in battery production, especially for battery modules.

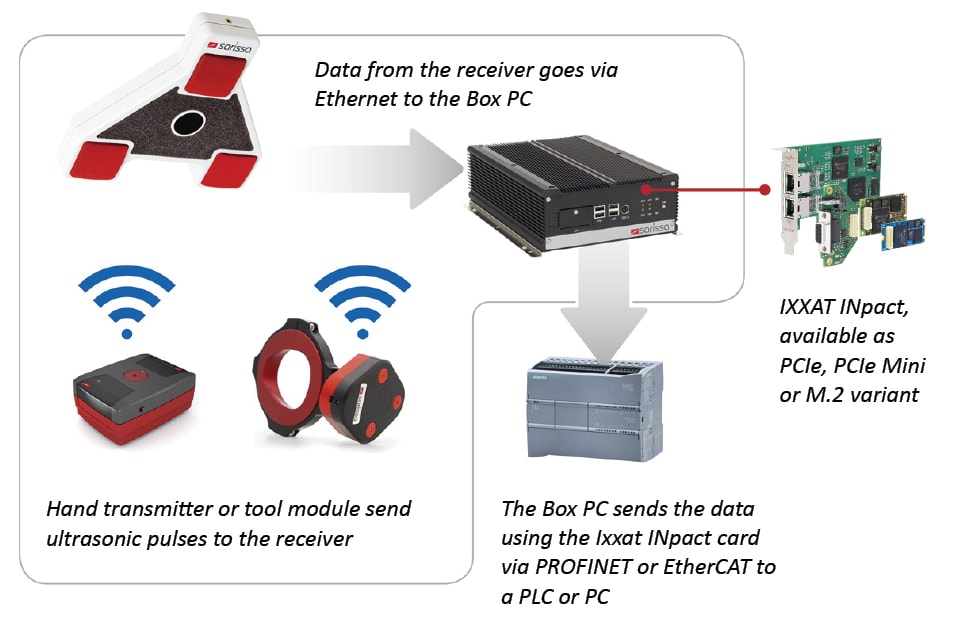

To appeal to customers with existing worker guidance systems, especially in battery production, Sarissa needed a way to offer its position determination system as a product for integration in external worker guidance systems. Its PositionBox is based on an industrial PC with application software programmed in .NET and connected via Ethernet TCP/IP with the PLC or PC in the customer’s worker guidance system. However, this configuration showed high latency in the complex processing of coordinates using PLC function blocks, especially in conjunction with PLC systems designed for cyclic processes with I/O data. Moreover, besides being highly complex, coordinate processing with PLC programming languages is uncharted territory for programmers.

We didn’t choose the Ixxat fieldbus card just because of its clear technological advantages. The relationship between Ixxat and Sarissa is based on years of close cooperation and mutual support, and that will continue in the future.

Volker Jauch, CEO Sarissa GmbH

To meet these challenges in the future, real-time coordinate processing and reliable mask data calculation need to take place in the PositionBox. A direct connection to the customer’s fieldbus and industrial Ethernet systems was the method of choice to ensure high data throughput with low latency. To make this connection, Sarissa chose the Ixxat INpact CE multiprotocol interface card. Working with Sarissa, in just a few weeks the HMS team created a protocol-independent programming interface based on .NET so that the card can be easily integrated in Sarissa’s application software. In addition to the certified PROFINET connection, Ixxat INpact fieldbus card also allows Sarissa to easily connect with other fieldbus and industrial Ethernet networks – a very flexible and future-proof solution.

Company: Sarissa GmbH

Country: Germany

Solution: PC interfaces

Industries: Industrial automation / Automotive

Products: Ixxat INpact CE Slave PCIe

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.