White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

RAXTAR, a global provider of vertical access hoists, relies on data analytics and HMS Networks' Ewon Flexy 205 gateway for predictive maintenance and performance optimization. They plan to explore AI models, including anomaly detection, for future enhancements.

With headquarters in Veldhoven, Netherlands, RAXTAR is a major international provider of vertical access hoists used on complex high-rise building construction and other industrial applications. These rack-and-pinion hoists improve efficiency and productivity at thousands of building sites around the world.

Collection, visualization, and analysis of data are key to maximizing the uptime and reliability of RAXTAR’s vertical hoist systems, with HMS Networks providing a complete data flow and communications solution all the way from the controlling PLC to a secure IIoT cloud platform.

“The costs of failure in the construction industry remain very high,” says Ruud van Gorp, Manager of Operations and R&D at RAXTAR. “In the Netherlands alone, annual costs are estimated at €5 billion, while globally, over 40% of construction companies estimate that their failure costs amount to 5% or more of the total budget for each project.” Digitalization is required to manage and limit these costs. Hoists are equipped with remote management capabilities through RAXTAR’s RX Control system. There is a clear shift towards data collection, reporting, and modelling, as well as integrating multiple information sources. Using a cloud-based platform promises increased efficiency, reduced risk, and higher profit margins on construction projects.

RX Control manages over 150 parameters of a construction hoist and provides exact information about the control system and behavior of the hoist. Collecting this data enables real-time insights into the hoist’s operation. By comparing live hoist parameters and analyzing all alarms, RAXTAR realized they could start implementing predictive maintenance throughout their global installed base. Now, a failure or a need for maintenance intervention can be predicted ahead of an actual breakdown, thereby avoiding downtime, which is a big part of the total cost of failure.

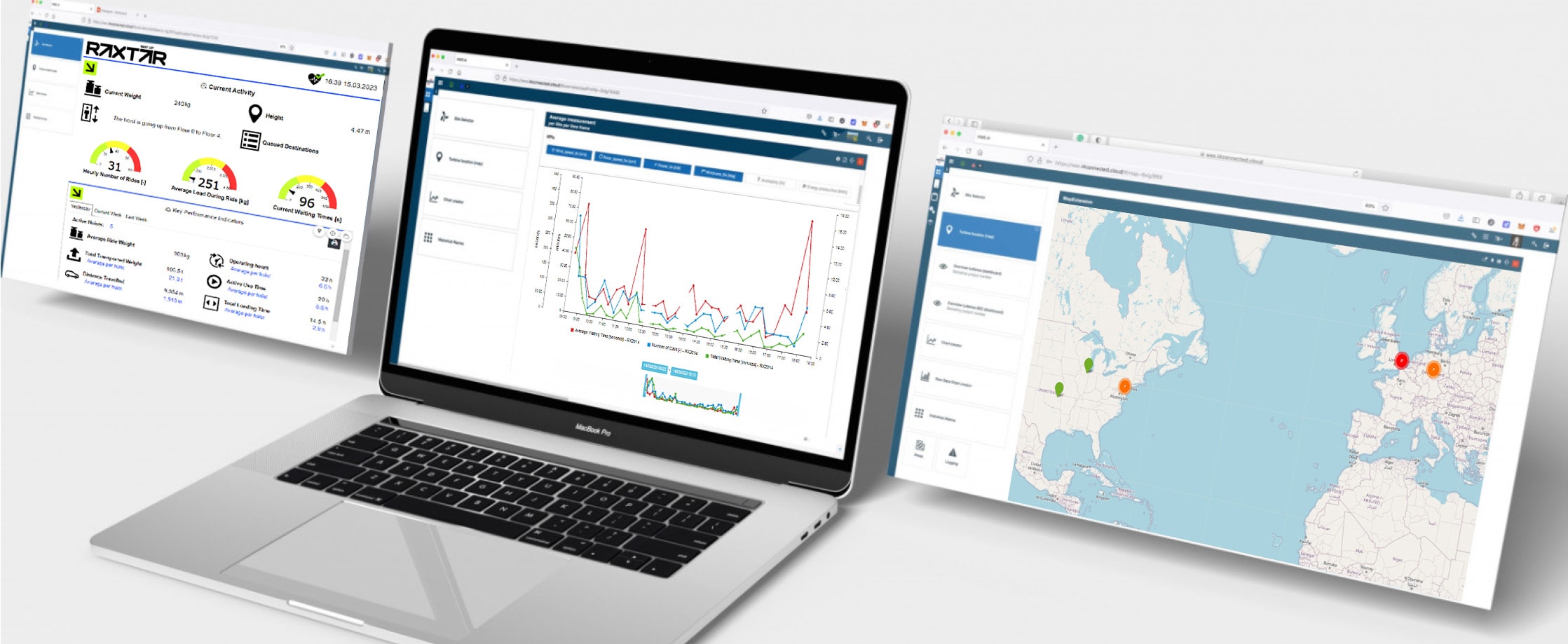

On the logistics side, RX Control provides critical insight into the building process by showing logistical KPIs, such as waiting times, ride times or load capacities. The information is made available through different system layers so relevant KPIs can be viewed as overall data, site data or individual device data.

HMS Networks gives us the insights to guarantee the hoists’ uptime and performance.

Ruud van Gorp, Manager of Operations and R&D, RAXTAR

By having access to this real-time information, the site manager is in control of the logistical process and can adapt the operation of the hoists to optimize usage and productivity.

The same information can also be used as input for machine development purposes and for the sales team to use when talking to prospective customers. In addition, new revenue streams based on a pay-per-use model are made possible. There is much interest in this approach since it limits risk on all sides: for example, transaction partners may agree to halve the upfront purchase cost but then agree a charge for usage, such as a price per metre that the hoist has moved.

Managing the data journey, all the way from source to secure storage, makes HMS a critical partner for RAXTAR as it proceeds on its own digitalization journey. Points on the “data route-map” that are managed by HMS include collection, transmission, secure cloud storage, and analysis.

For accessing data generated by the hoist, RAXTAR uses HMS’ Ewon Flexy 205 gateway, not only as a remote access tool, but also as a data gateway for secure MQTT messaging. This makes it easy to collect and monitor the critical data needed for predictive maintenance and performance monitoring.

The site manager is in control of the logistical process and can change the behavior of the hoist to better suit the process. He can for example make reservations to hoist when important deliveries come in, or modify half of the hoists during the morning so that they will only move to the complete top, to optimize the behavior at important (rush) hours.

Web-based i4 dashboards enable RAXTAR to efficiently monitor hoists’ performances

To manage data storage, visualization and analysis, Ewon’s i4 solutions provide an intuitive web-based dashboard, IIoT platform, data analysis interface and visualization module. i4 solutions connect machines, systems, and buildings digitally and work seamlessly together with the Ewon Flexy. KPI data from connected equipment is displayed in real time, and can be processed, analyzed, and integrated into any IIoT/IT application. This enables smart applications such as remote monitoring, predictive maintenance, and business model optimization.

Another challenge in RAXTAR`s machine is the communication from the ground cage to the hoist. This is a critical safety line that needs reliable communication in order to work properly. This is covered by using the HMS Anybus Wireless Bridge, supporting wireless Ethernet communication up to 400 meters!

“The future is using AI models to analyze data in an automated way,” predicts Head of i4 solutions, Stefan Hauck. “Working in combination with colleagues at HMS Labs in Sweden, our internal department responsible for driving and shaping disruptive technologies, we are exploring more exciting ways to further utilize AI. An example is anomaly detection, a machine learning technique designed to eliminate false positives and ‘alarm spam’”. A promising future!

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.