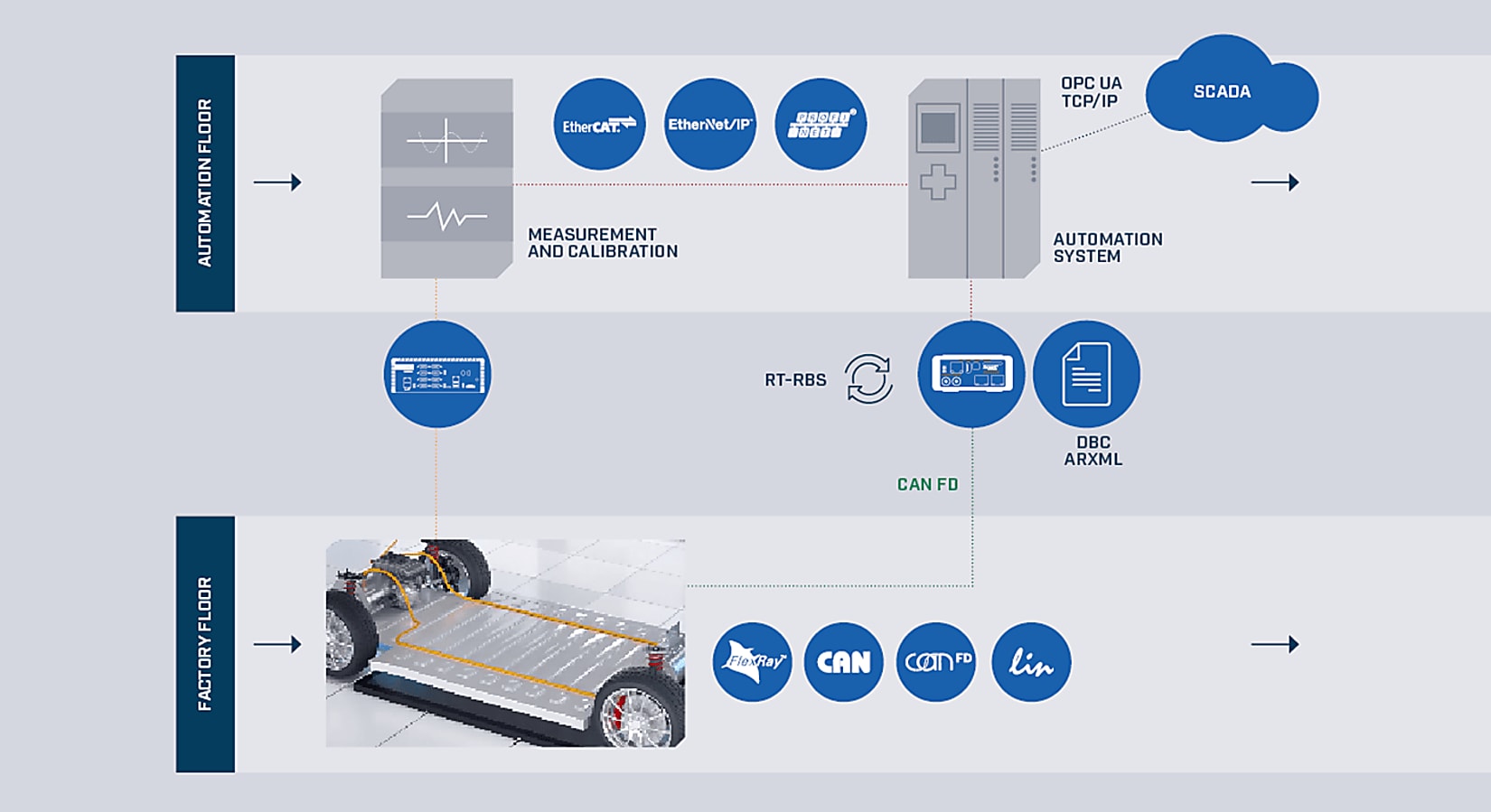

The proportion of software in modern electric vehicles is constantly increasing, which also means an increase in data and communication solutions. From simple control units to battery management systems and complex drive controls to the connection of in-vehicle networks such as Automotive Ethernet, CAN FD, LIN or FlexRay to the factory environment (e.g. as part of EOL tests) – countless data must be exchanged, read and interpreted. Intelligent gateway solutions from HMS make it possible to connect both worlds via a central platform consisting of hardware and software – from end-of-line production to quality assurance, development and testing to test bench communication.

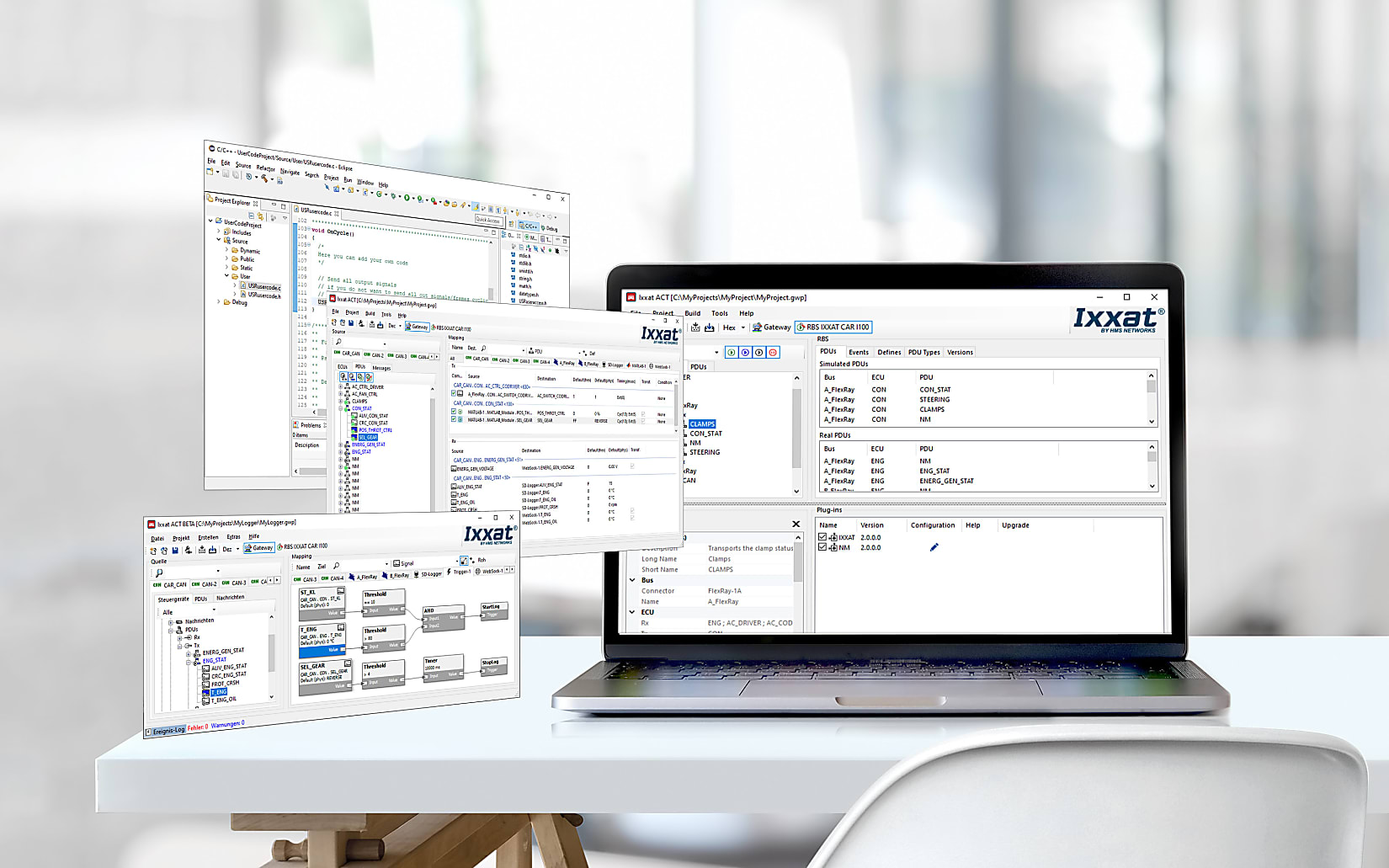

Configure instead of program

The intuitive ACT configuration tool offers maximum flexibility when setting up applications. This software is used to define the behavior of the gateways once and then transfer it to the device. Several applications can be operated in parallel. The combination of ACT configuration software and hardware offers a fully functional and intuitive standalone solution that saves users a huge amount of time and at the same time does not require any programming knowledge.

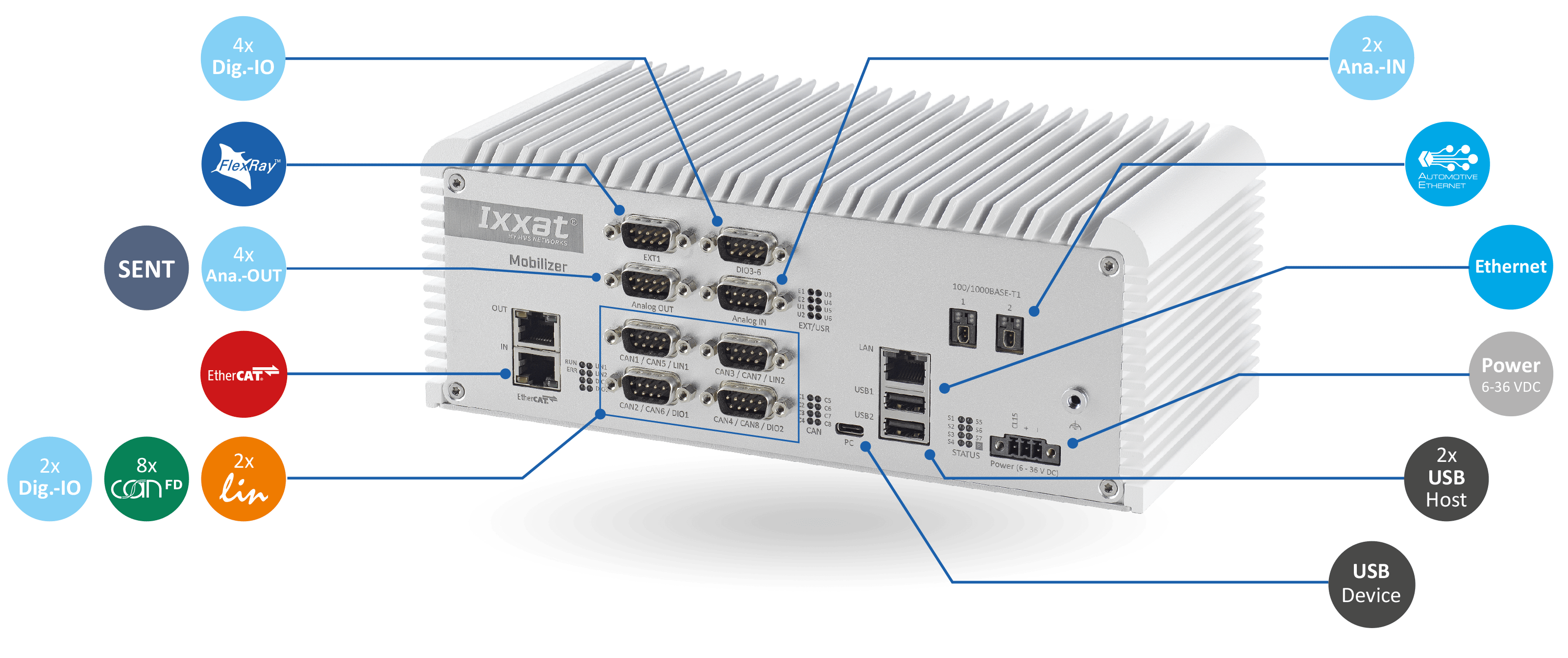

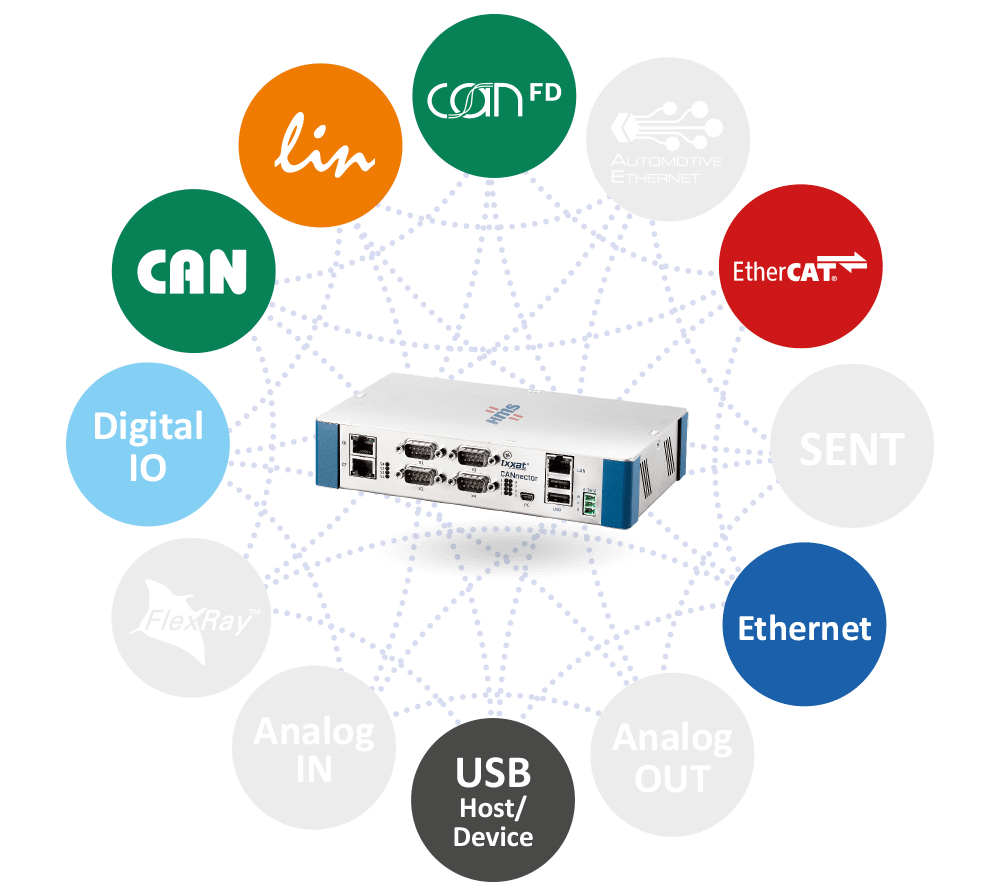

One gateway - all protocols for maximum flexibility

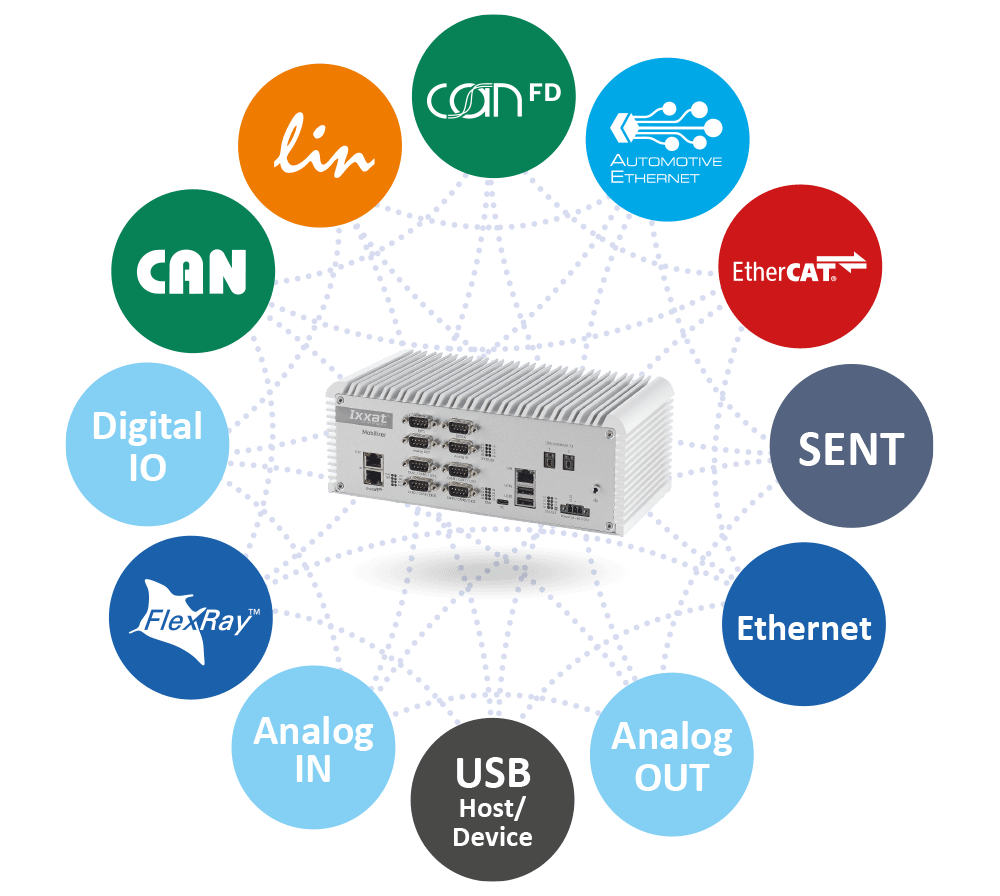

The Mobilizer series enables the combination of all common communication protocols in the automotive industry: Automotive Ethernet, EtherCAT, CAN CC, CAN FD, LIN or Flexray can be connected to one another via a single gateway. Users benefit in particular when applications, DUTs, protocols and interfaces change frequently. This increases the flexibility of the application solution and thus saves time and effort when changing projects.

Remaining bus simulation with integrated Matlab/Simulink models

While comparable products often require a lot of effort to program a remaining bus simulation manually, the Mobilizer series offers a fully integrated application that can be configured using ACT software simply by dragging and dropping and then transferred to the platform in just a few clicks and without any programming effort. Matlab/Simulink models integrated in the software also make it easier to create predefined applications - which saves even more time.

Eight CAN channels with high signal stability

The Mobilizer product family has eight CAN channels. Each of these is automatically a CAN FD channel. All CAN channels are also "SIC compliant" (Signal Improvement Capabilities).

This allows users to implement combinations with several components at the same time. This offers maximum flexibility when designing applications. Thanks to the special SIC transceivers, the Mobilizer series also ensures high signal stability – the customer benefits from a stable and reliable CAN-FD connection.

Maximum transmission speeds thanks to Automotive Ethernet

The Mobilizer series has the new Automotive Ethernet standards 100Base-T1 and 1000Base-T1 in all models. Users therefore benefit from transmission speeds of 100 or 1,000 Mbit/s, low latency times and lightweight, space-saving and cost-effective cabling. The Automotive Ethernet standard meets all communication requirements for modern in-vehicle networks.

Integrated analog and digital I/Os

Depending on the model, the products in the Mobilizer series have up to six digital I/Os as well as up to two analog in and four analog out interfaces for recording and processing process signals for the control system. Depending on the application, users can connect several measuring devices to one device and process their signals in parallel.

CRC & Alive Counter for secure data encryption

The integrated plug-in system from HMS regulates the type of secure data encryption. This means that the data does not have to be continuously encrypted with a lot of programming effort, but only once using a plug-in. This means that users do not have to worry about securely encrypting their data every time they change projects.

Compatibility through message catalogs

The Mobilizer series can process data at different levels (message, PDU, signal) by importing all common message catalogs (DBC, ARXML, Fibex and more).

DIN rail mounting and desktop use

The Mobilizer product family is mainly used as a desktop device by engineers and developers in vehicle development, while at the same time it is used in control cabinets in vehicle test benches and control rooms. Thanks to the optional DIN rail mounting (DIN Rail), all Mobilizer models can be used in both areas of application without restrictions.

Robust housing for maximum performance

The housing of all Mobilizer models (protection class IP40) was specially designed for use in production environments. Thanks to a special aluminum cooling fin system that enables continuous heat dissipation, use in ambient temperatures between -40 and +70°C is possible without any problems. An integrated temperature monitoring system also continuously checks all critical components so that overheating is not possible despite high computing power.

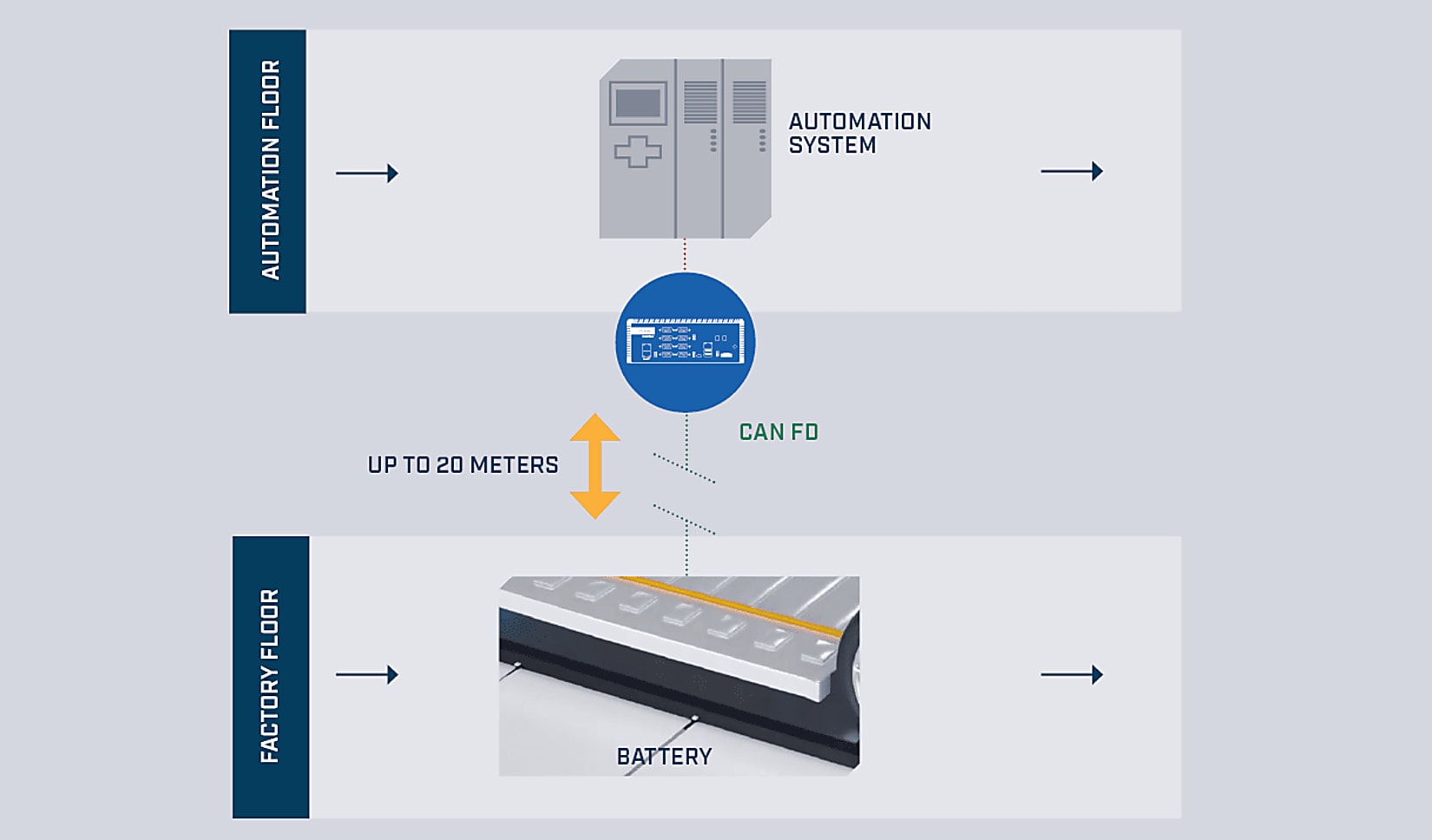

Communication with automation environment

Signals from in-vehicle networks can be output and sent to the automation environment via the integrated EtherCAT interface or Ixxat's own Generic Ethernet. Surrounding systems thus have access to the IVN data and can also receive information about the device status. This means that users not only keep a close eye on their application and automation, but also on the status of their systems at all times.

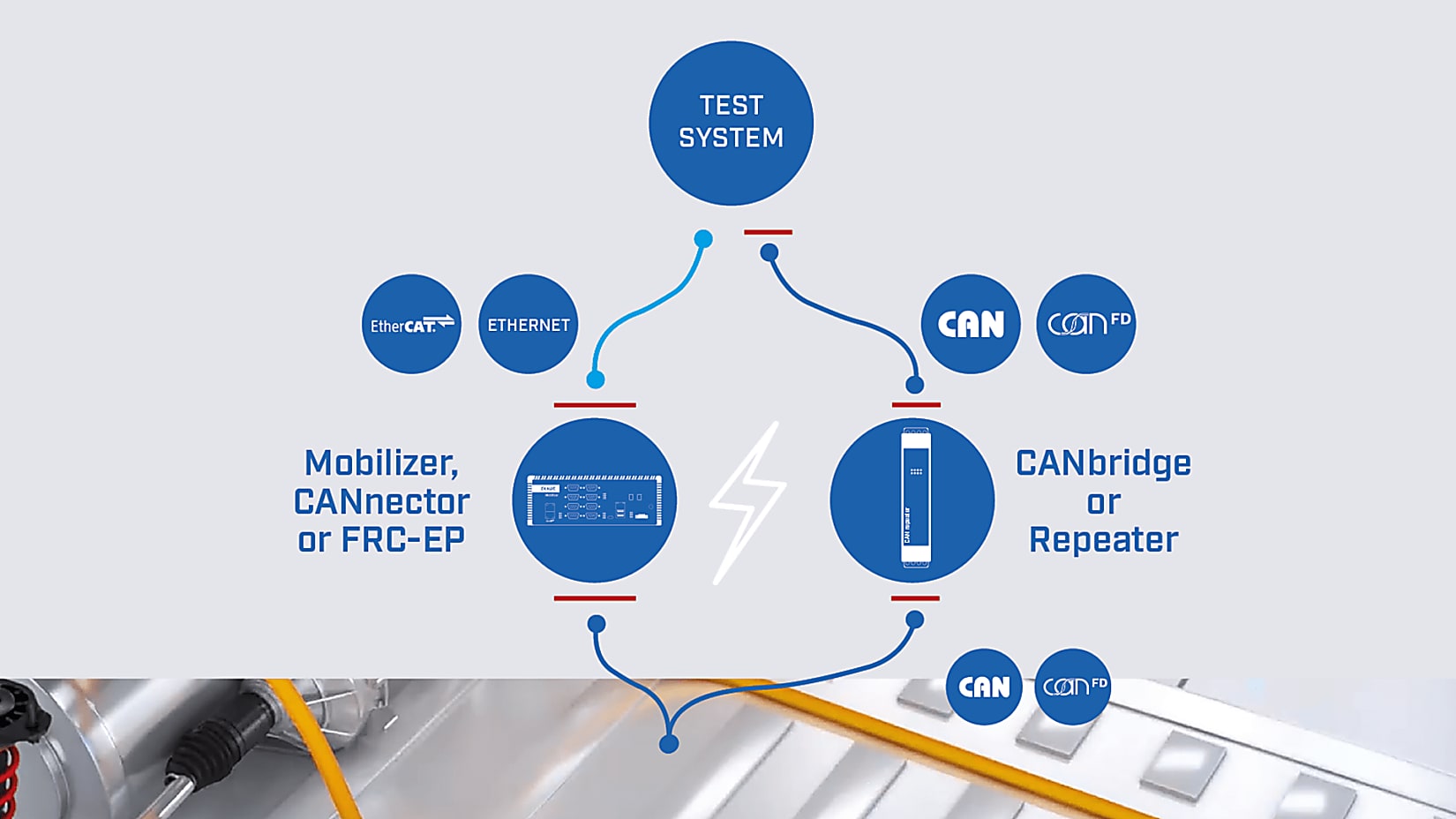

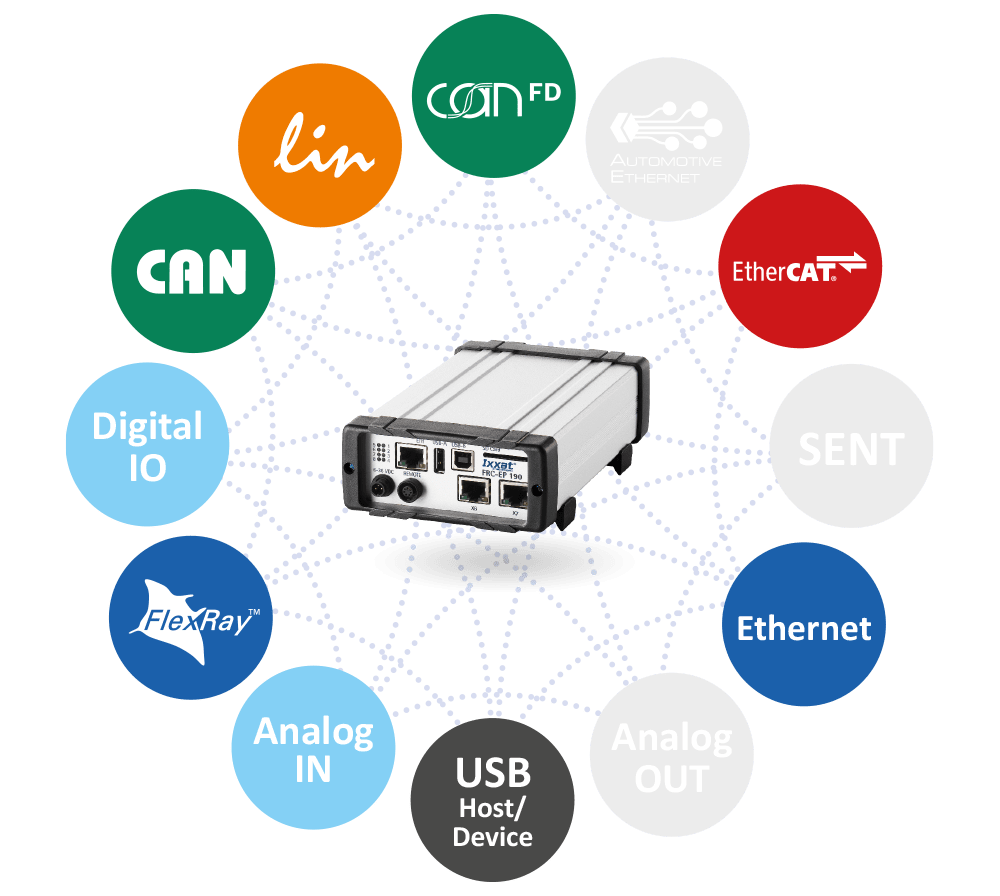

The FRC series was developed for the most demanding applications in the area of end-of-line testing and for the communication requirements of test bench connection. With this product, gateway and simulation tasks (RBS and/or Simulink models) can be created in various levels of complexity.

The CANnector has interfaces for CAN, CAN FD and LIN as well as digital inputs and outputs, while the FRC series also offers FlexRay and K-Line.

Communication with test automation differs greatly from in-vehicle communication, as here control information mainly has to be transmitted over longer distances (20 to 50 m) between the vehicle and the control center. The EtherCAT protocol is often used as an interface to test bench automation for exchanging measurement data. The "Generic Ethernet" protocol developed by HMS also offers greater flexibility and diagnostic functionality. It is therefore the ideal interface between the in-vehicle network and test bench automation.

Frequently asked questions

Our automotive products support CAN (CAN CC and CAN FD), LIN, FlexRay, Automotive Ethernet, CAN XL and Sent.

HMS products enable access to vehicle communication networks. In addition to the purely physical layer, the products interpret message catalogs and diagnostic data (e.g. software updates). To start up communication, residual bus simulations can be easily created. In addition, the products can be connected to PCs and controllers.

The CANnector family represents the economical standard class in the vehicle world. It allows simple gateway applications to be implemented between CAN- and LIN-based in-vehicle networks, PCs and controllers. At the same time, logging and visualization tasks are supported. The Mobilizer and FRC-EP series completes our offering in the performance area with FlexRay, Matlab/Simulink and residual bus simulation support.

A residual bus simulation is required when nodes in an in-vehicle network are not available as real control devices, but signals from them have to be simulated. The remaining, non-physical part of the network (the remaining bus) must therefore be simulated. The creation of a residual bus simulation can be accomplished within a few minutes with our products using existing message catalogs.

Message catalogs such as DBC, Fibex, ARXML or A2L are description formats for the complete communication within an in-vehicle network. These files are used to describe communication settings, data formats (messages, coding of signals within the messages, etc.), security regulations and timing of the participants (control devices) for a complete network.

Due to the use of high-voltage components, electromobility places higher demands on the electrical protection class for the communication products used. Voltages in the range between 400 V, 800 V or even 1000 V, with which HV storage and drive systems operate, can, in extreme cases, induce potential shifts on communication lines and thus destroy communication components. In addition to a precise grounding concept, protection can be achieved by an increased galvanic isolation of the communication interface, e.g. by using galvanically isolated CAN repeaters. As ballasts, these can protect expensive installations from damage.

Depending on the application, different control buses are used. For example, in the area of test bench automation EtherCAT is often used, while in the area of manufacturing and end-of-line testing, automation is dominated by PROFINET, EtherCAT or EtherNet/IP.

In principle, all vehicle data (i.e. the communication between the control units) can be logged. There are different types of logging: message-based and signal-based logging. With message-based logging, all data within the recorded messages is recorded as raw values. With signal-based logging, the messages are decoded before logging and the corresponding physical signal values are recorded according to the definitions within the message catalog.

The engineering tool ACT is the heart of our automotive products. With the tool gateway applications are created, residual bus simulations are configured, and visualizations are described, compiled and loaded onto the products of the FRC/CANnector families, in which the applications then run standalone. The ACT was developed with a high level of user-friendliness in mind, so that simple and targeted creation of configurations is possible with the greatest possible flexibility.

The proportion of software in modern vehicles is continually increasing. This makes it easy to perform improvements and corrections to vehicle components both in development and in production or even at the customer. If an FRC-EP190 or a CANnector is already in use in production, no separate VCI is required to apply software updates. In addition to a diagnostic protocol support (such as DoIP, XCP and similar), the products can also be used as “remote interface” and support at this VCI functions in parallel to gateway functions.

Electric mobility: communication solutions for production and test. Find detailed information about the solutions and products we offer within our brochure.

Have a communication expert from HMS contact you to discuss your specific requirements.