Q&A

AGVs and AMRs. What's the difference?

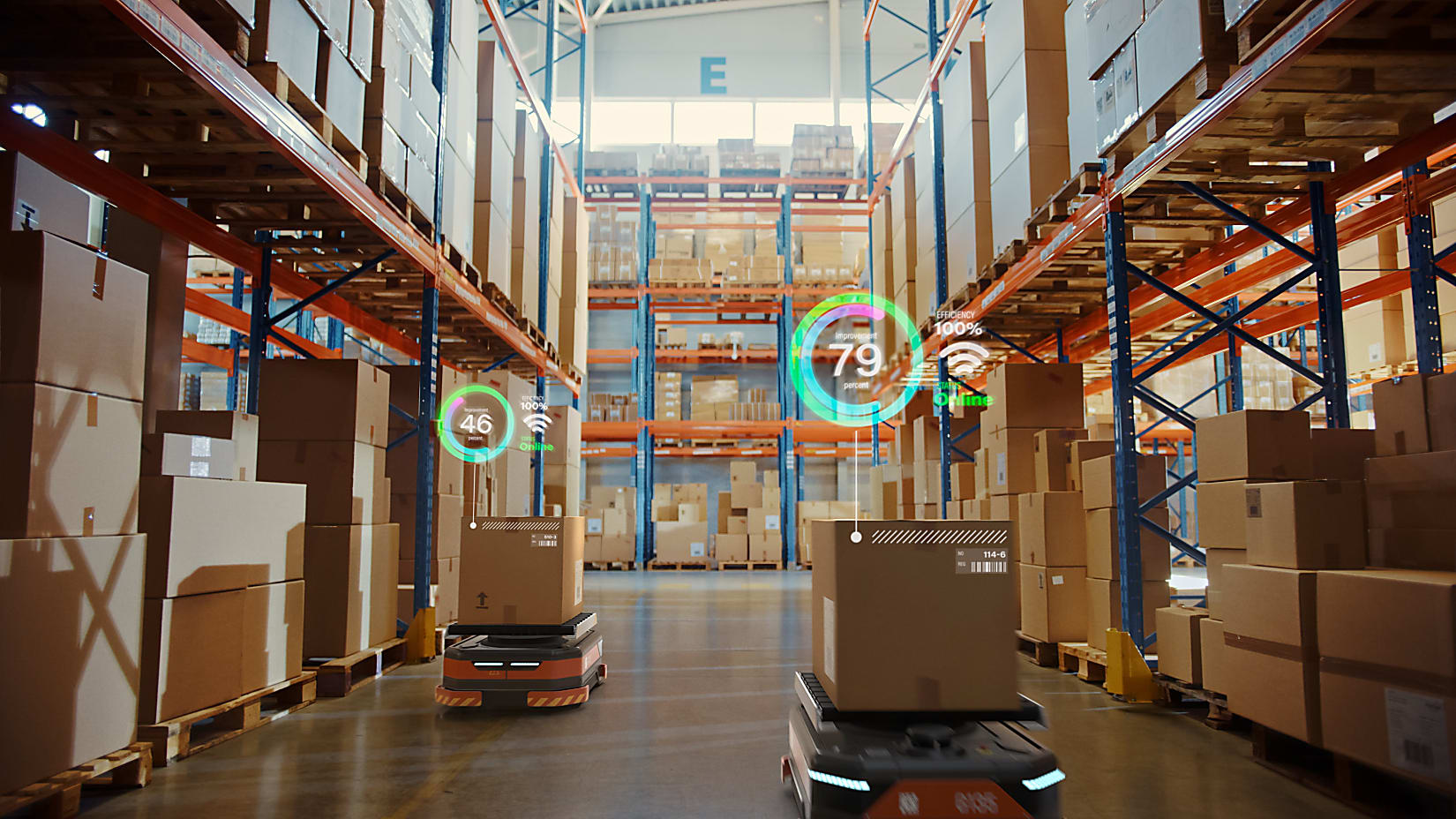

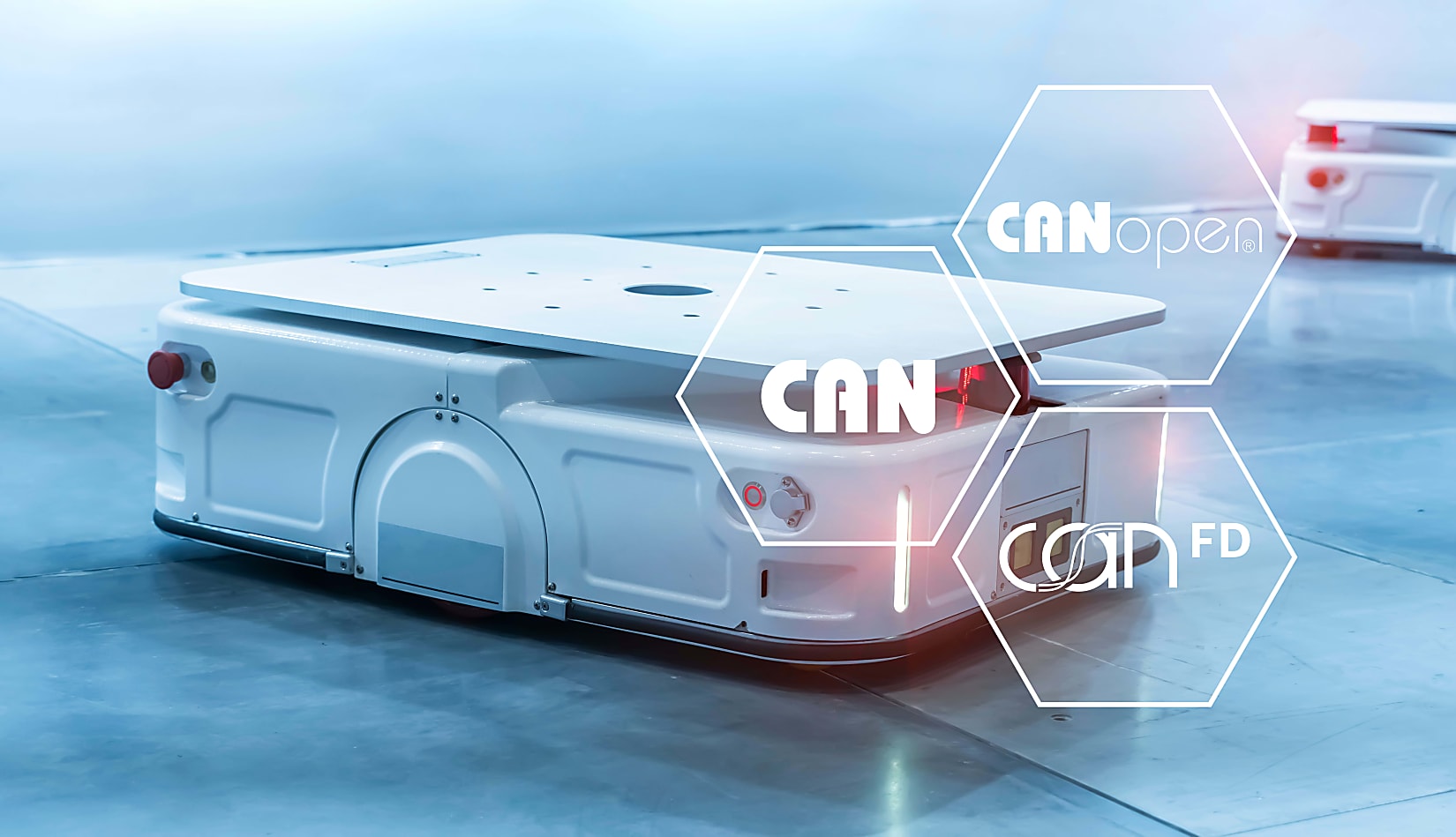

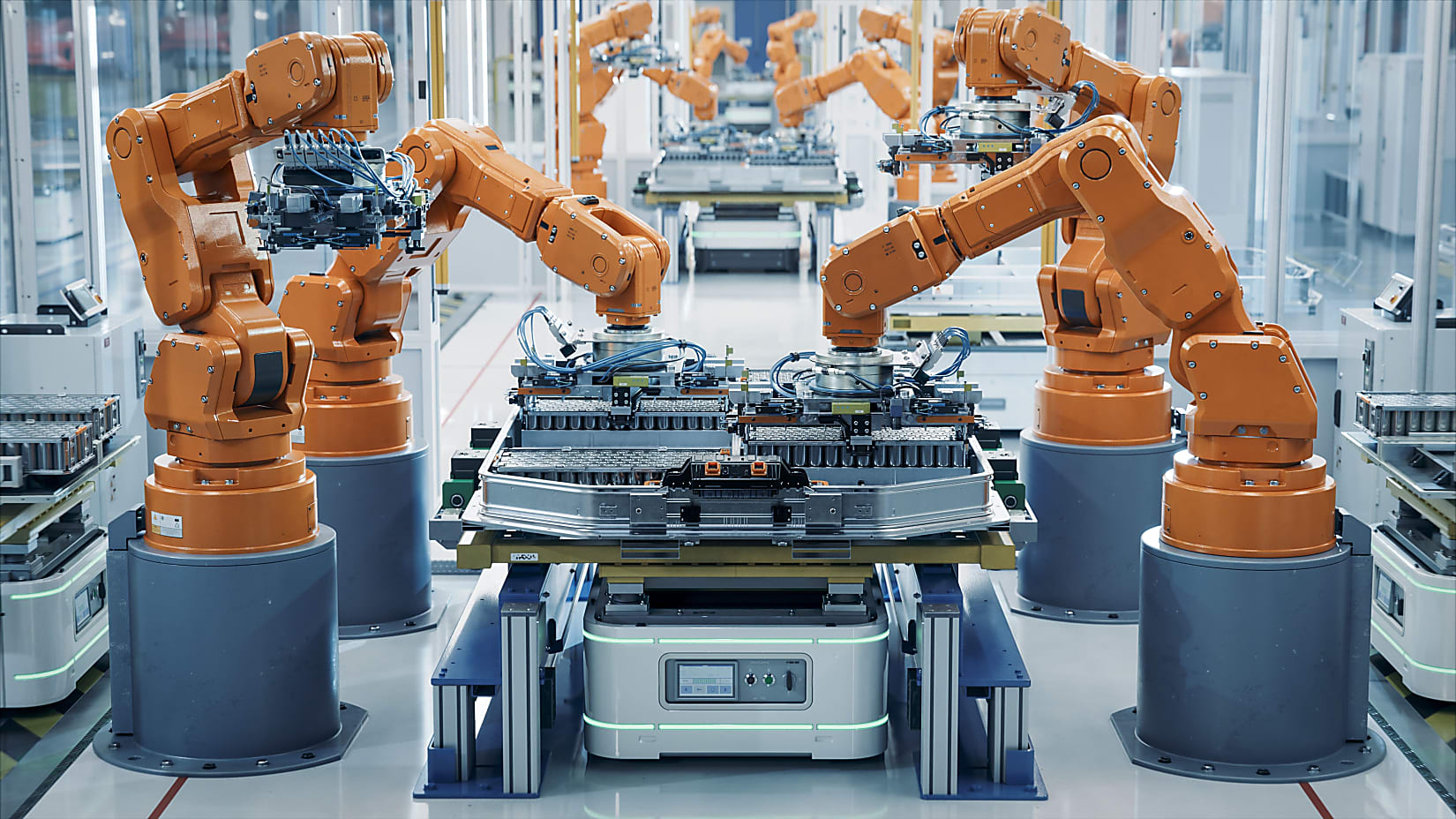

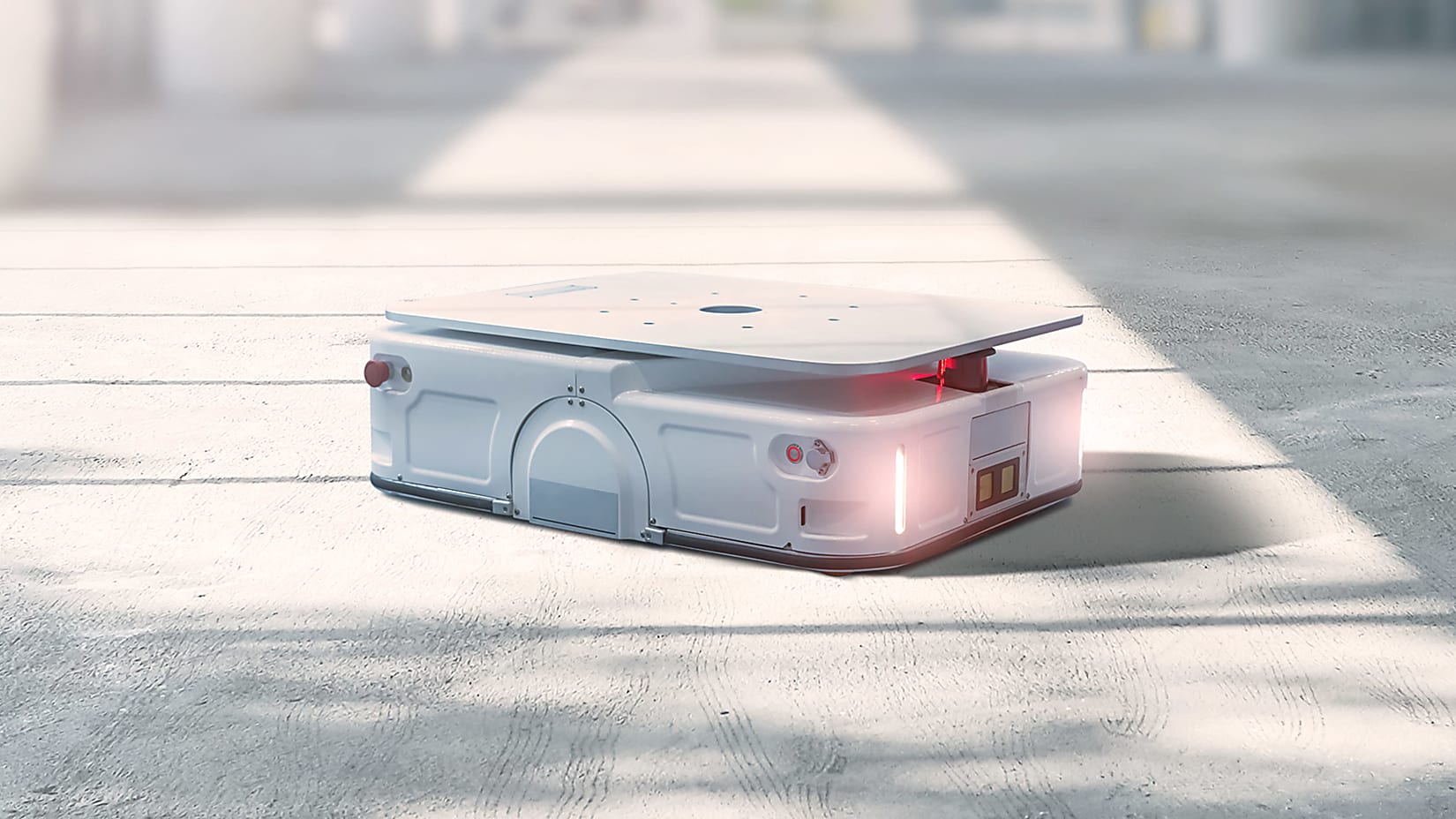

Automated guided vehicles (AGVs) use guiding infrastructure to follow predetermined routes. If an object blocks an AGV’s path, the AGV stops and waits until the object is removed.

Autonomous Mobile Robots (AMRs) are more dynamic. They navigate via maps and use data from cameras, built-in sensors, or laser scanners to detect their surroundings and choose the most efficient route. If an object blocks an AMR’s planned route, it chooses another route.

As AMRs are not reliant on guiding infrastructure, they’re cheaper and quicker to install and can adapt to logistical changes. Although Mobile Robots is an umbrella name, the most widely used term for driverless vehicles in general is "AGVs."

Does the new EU Machine Directive apply for AGVs/AMRs?

Yes, The EU Machinery Directive (Directive 2006/42/EC) extends the definition of "machinery" and addresses new technologies, software-based safety features, and self-learning systems. Mobile robots such as AGVs and AMRs produced in, or operating in Europe need to abide the directive.

What is the new EU machine directive?

The EU Machinery Directive (Directive 2006/42/EC) ensures the safety of machinery sold or marketed in the EU and forms the basis for the CE marking, indicating mechanical and electrical safety.

Standards such as ISO 12100 and ISO 13849-1 aid manufacturers in conforming to this directive. In 2023, a new version of this directive, known as the Machinery Regulation (Regulation (EU) 2023/1230), was published, which will be mandatory by January 14, 2027.

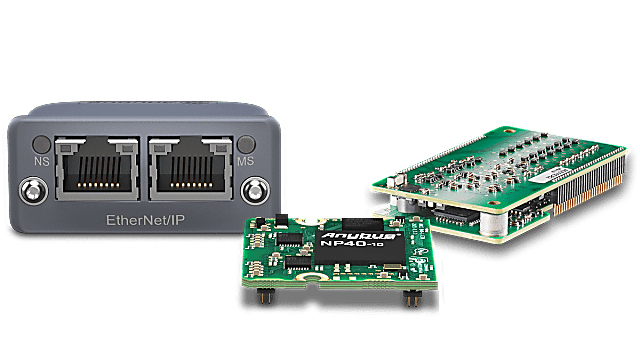

What are the effects of the EU machine directive?

It will mean that AGVs will need to communicate with industrial safety standards such as ProfiSafe, CIP Safety etc. in order to be used on the European market.